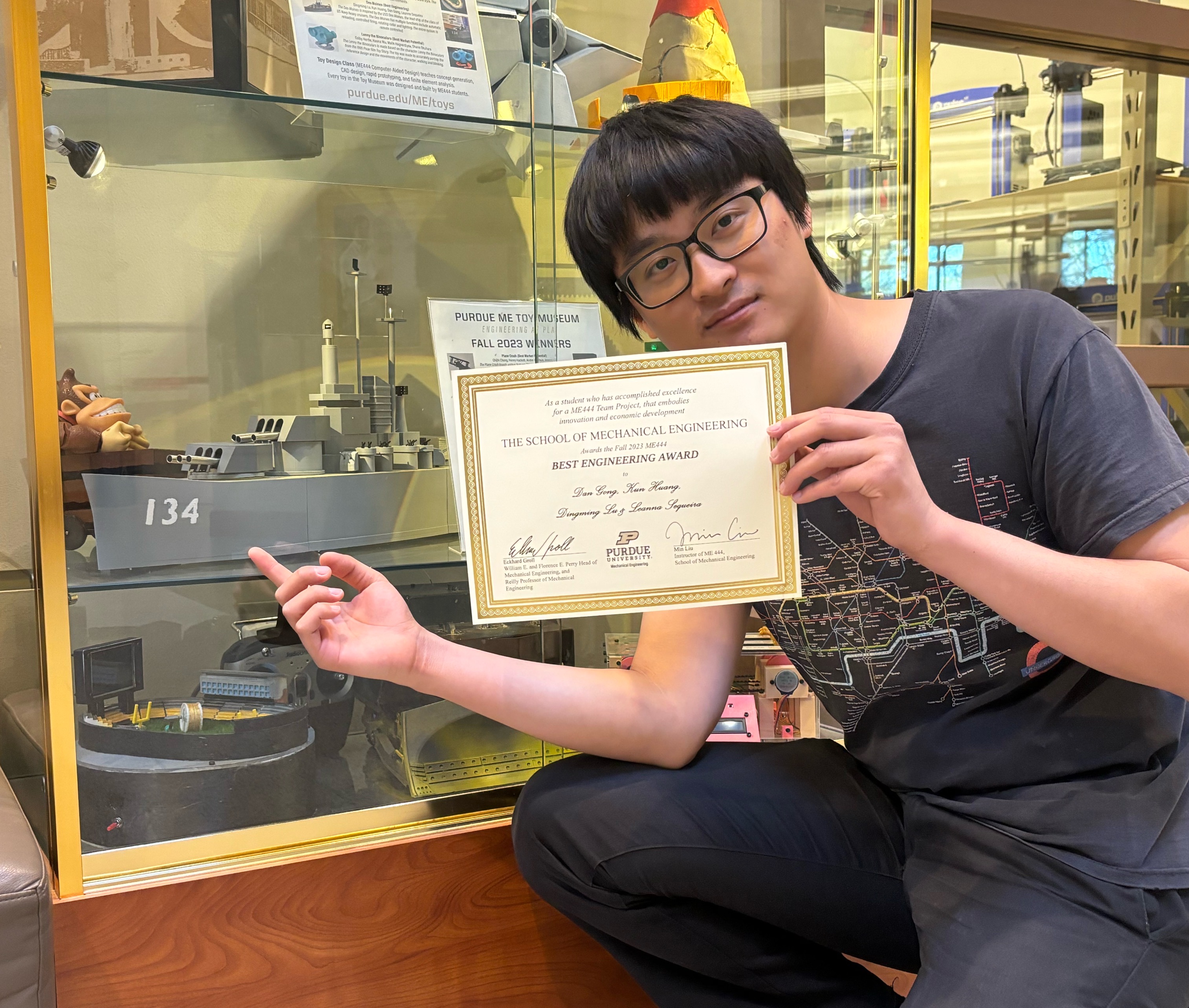

Intro

Date: October – December 2023

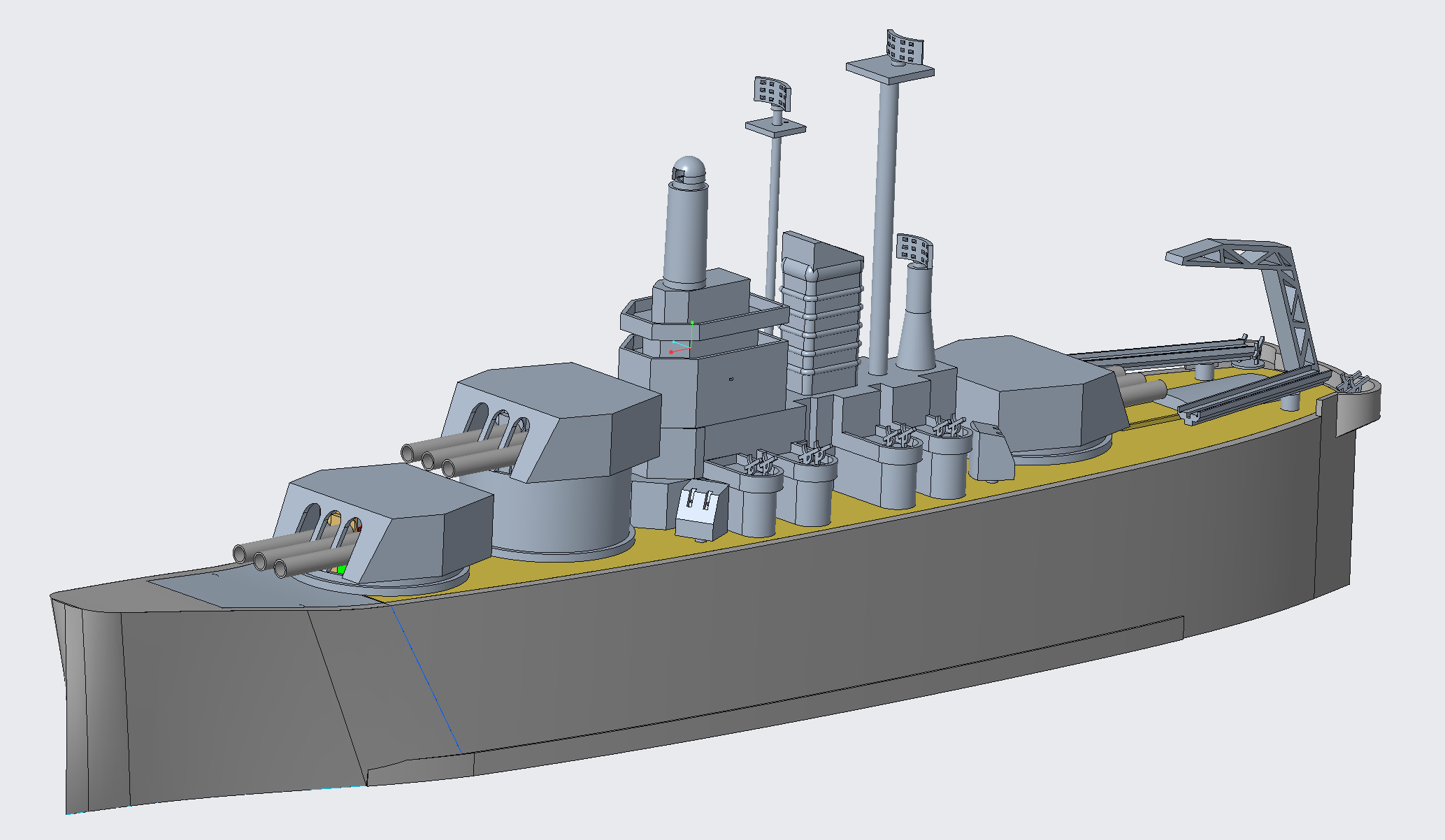

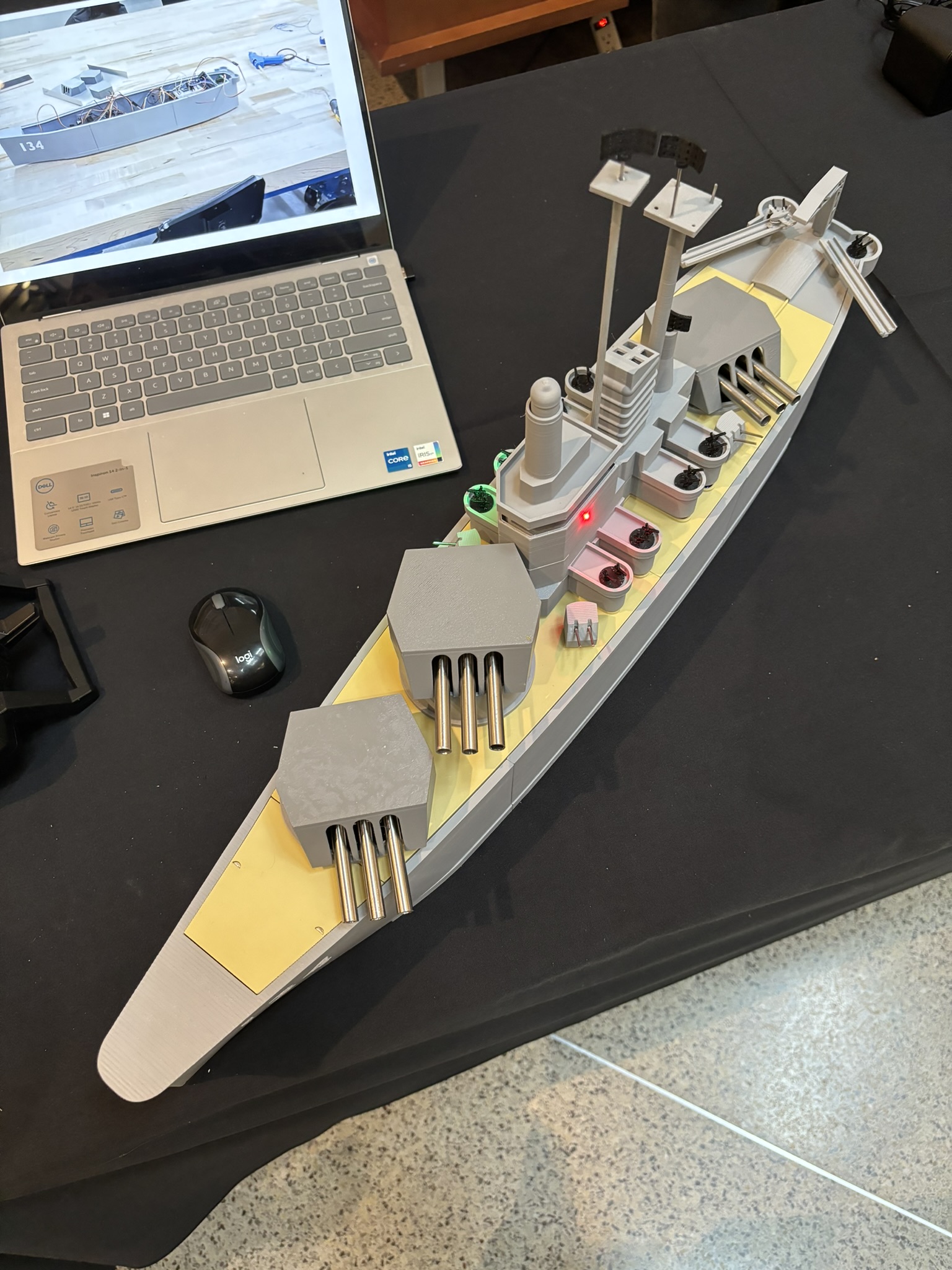

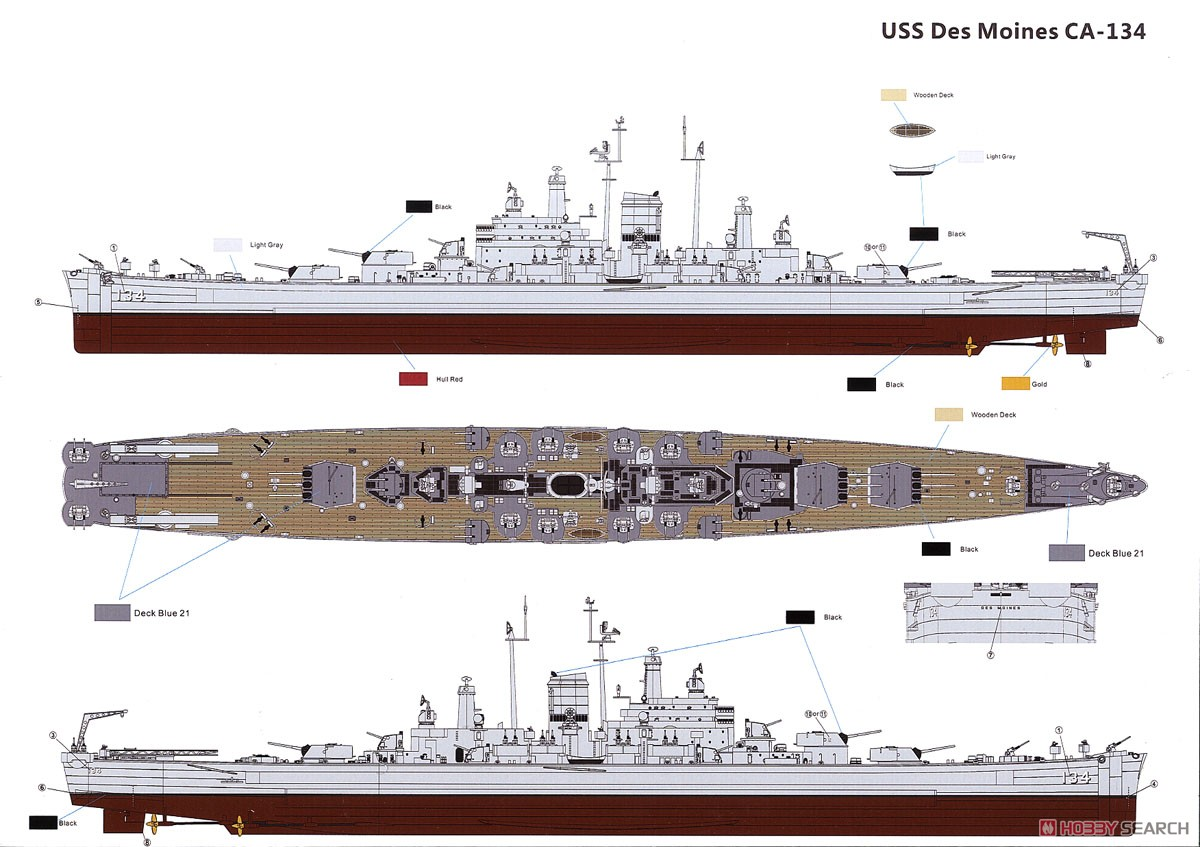

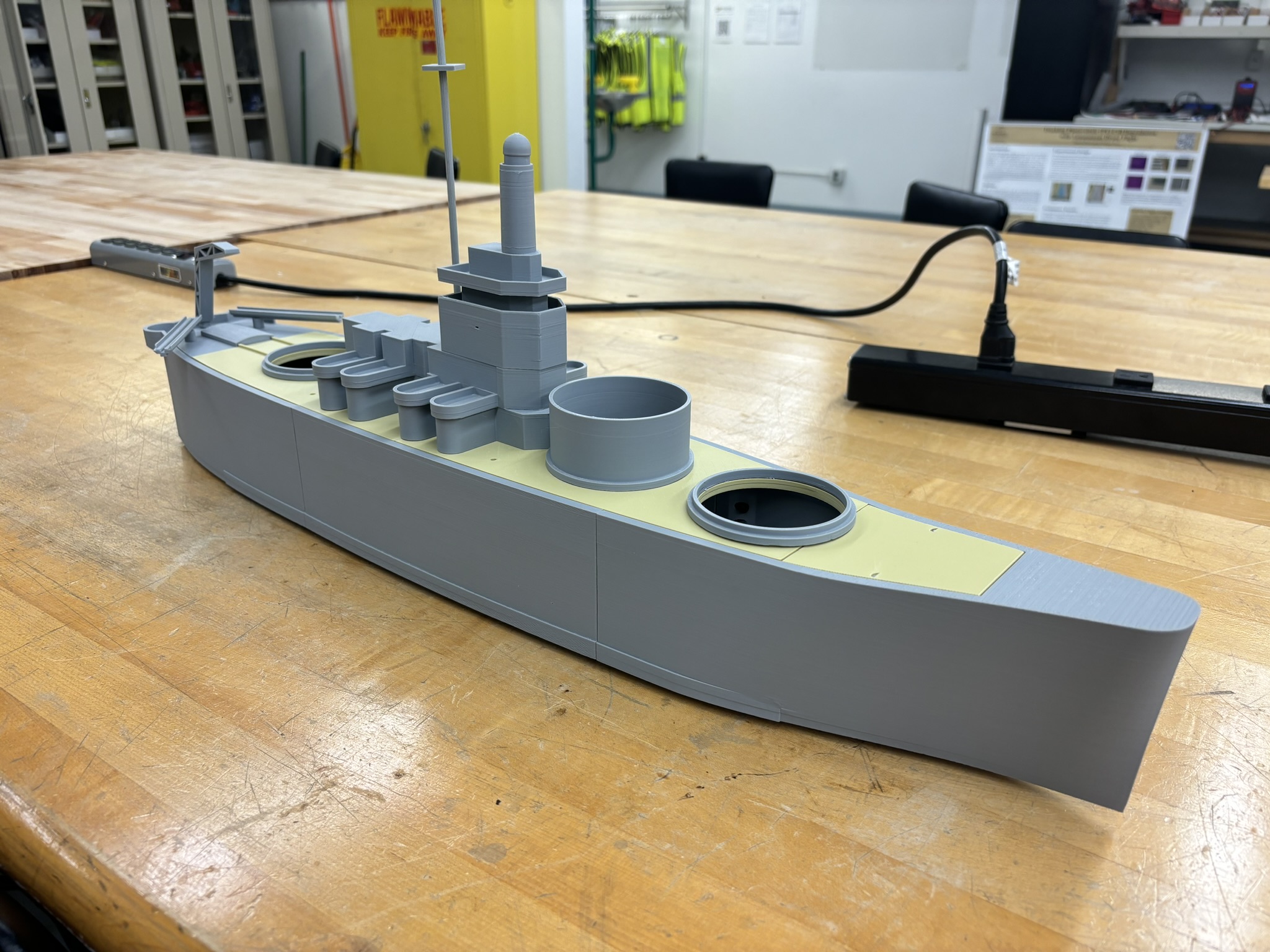

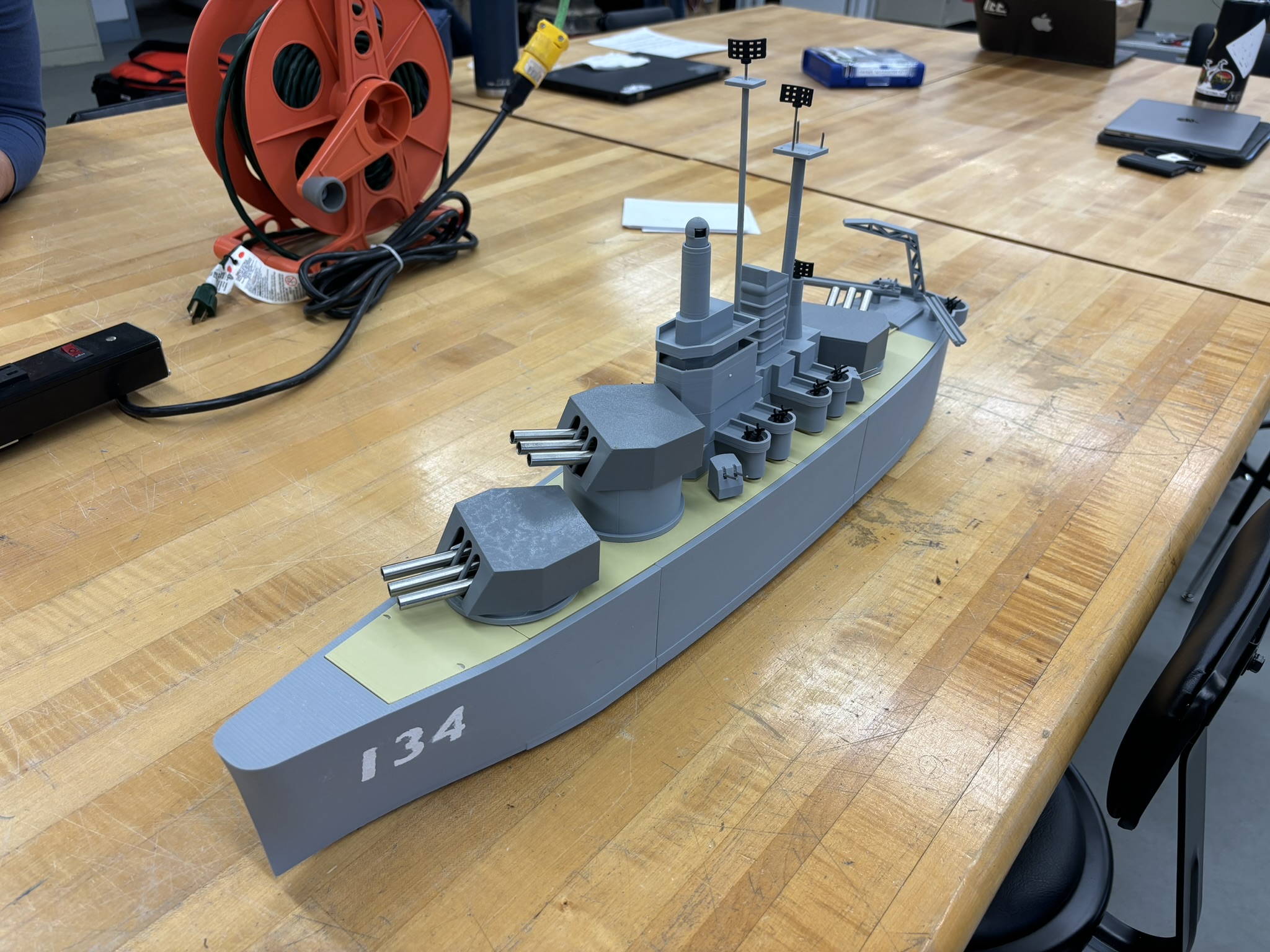

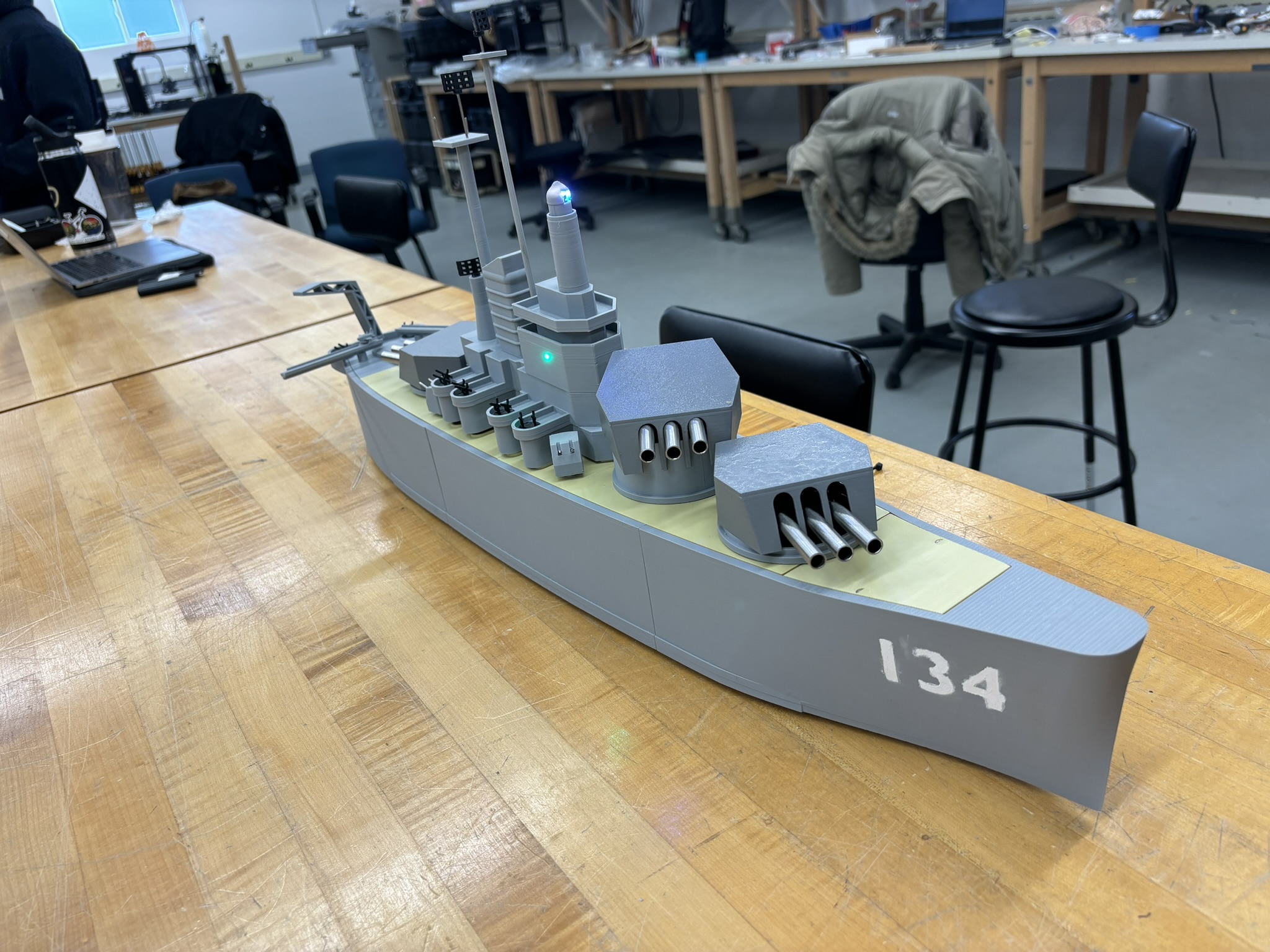

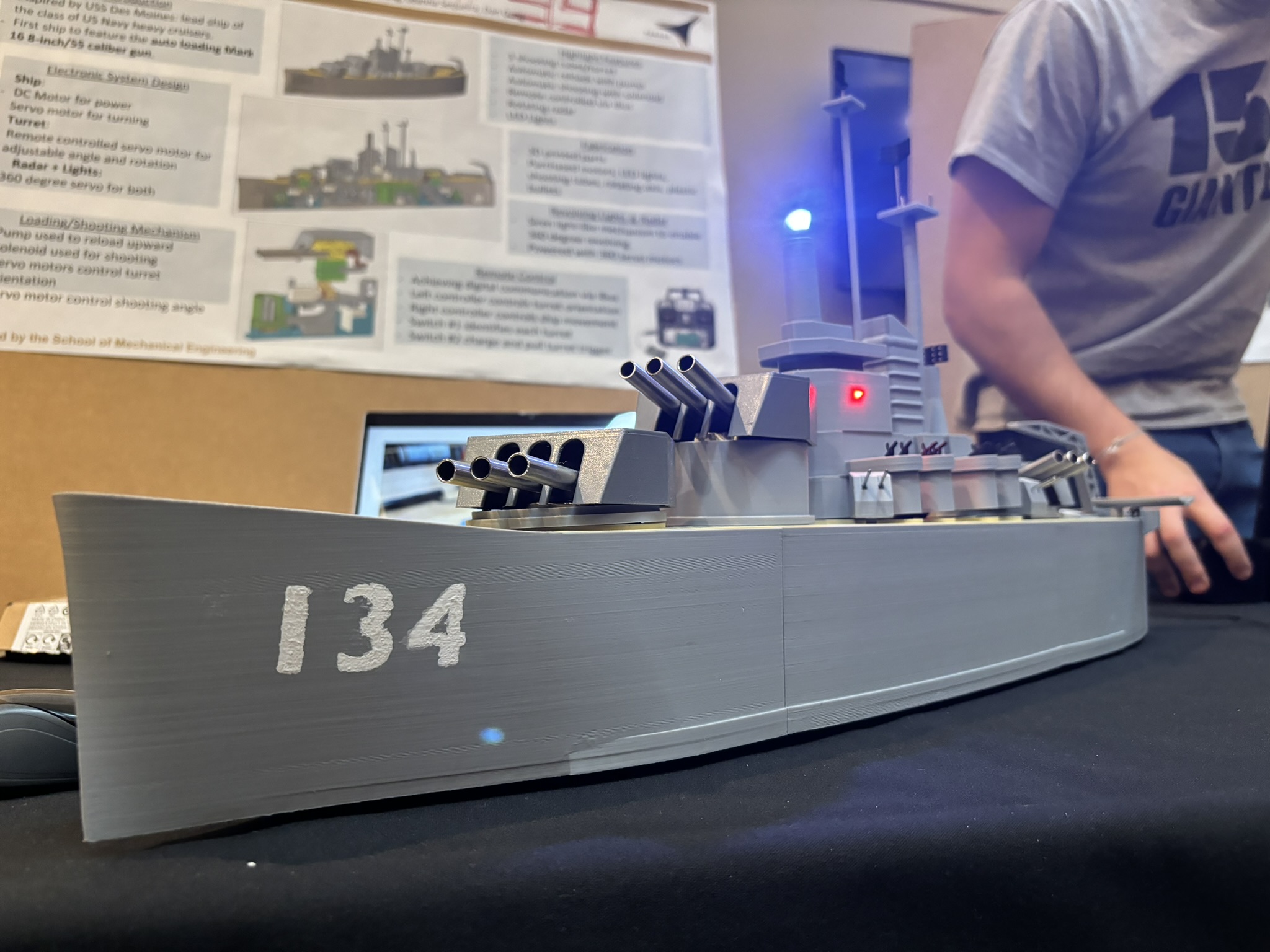

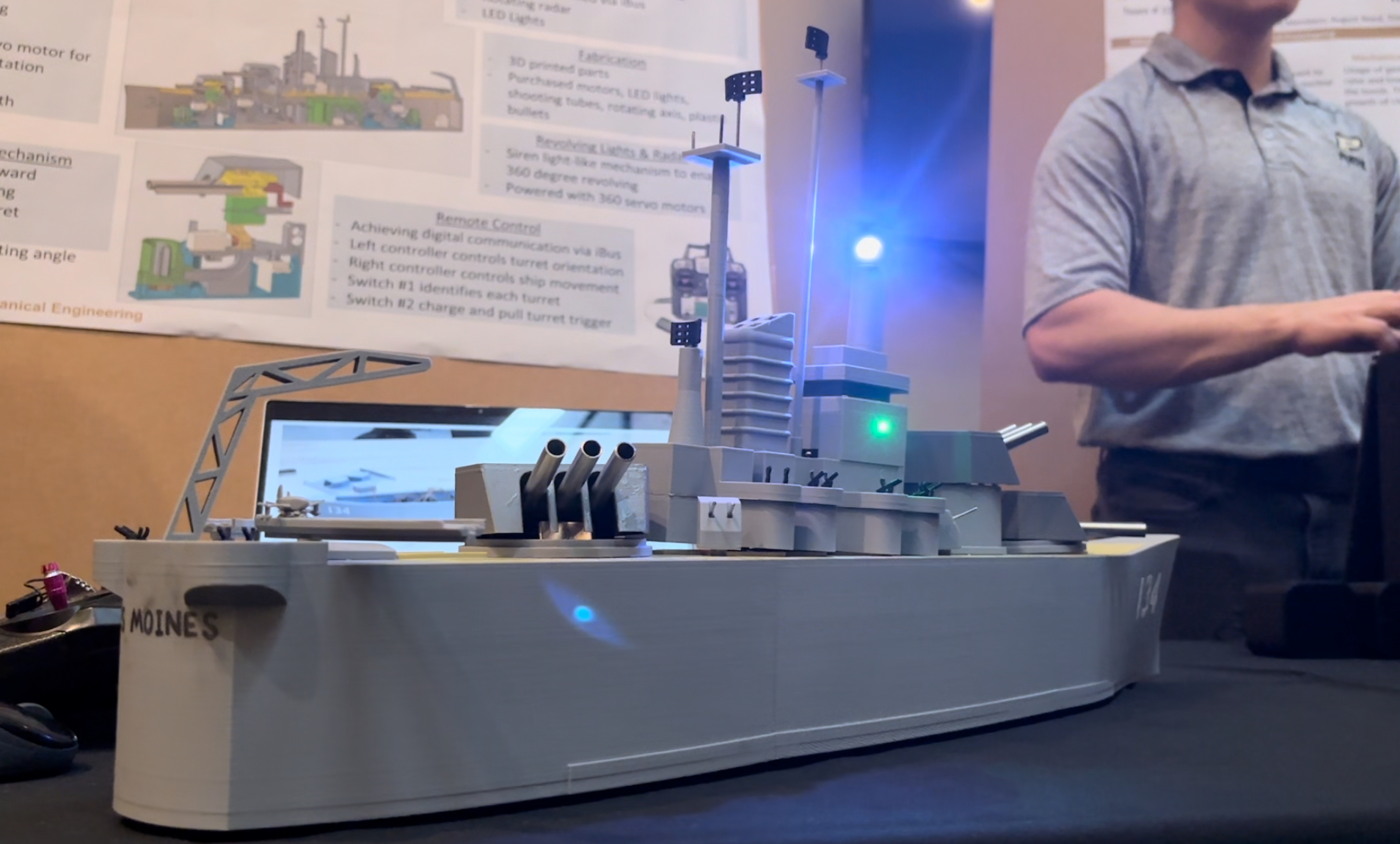

We built a RC Des Moines! But not to scale…..

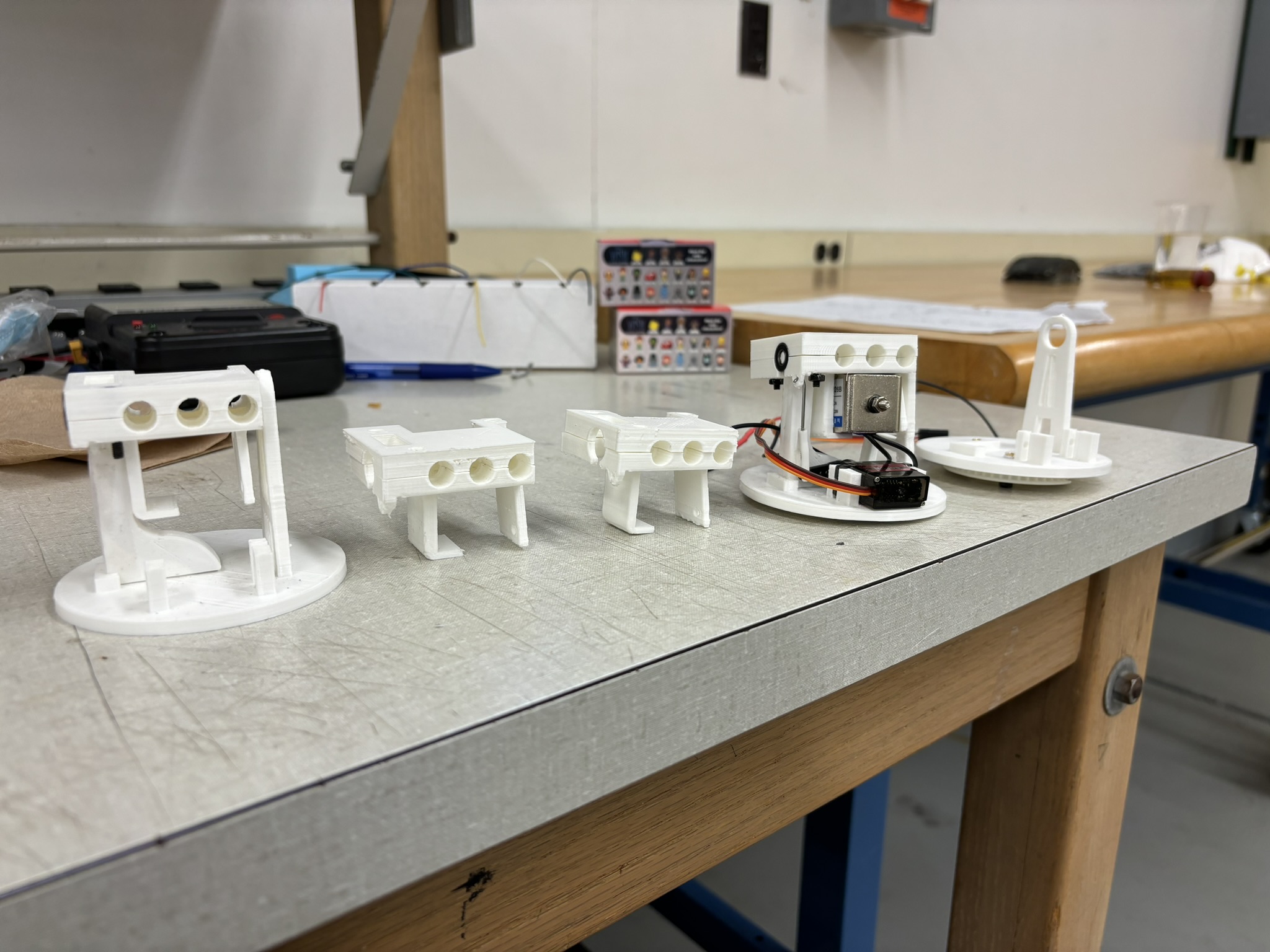

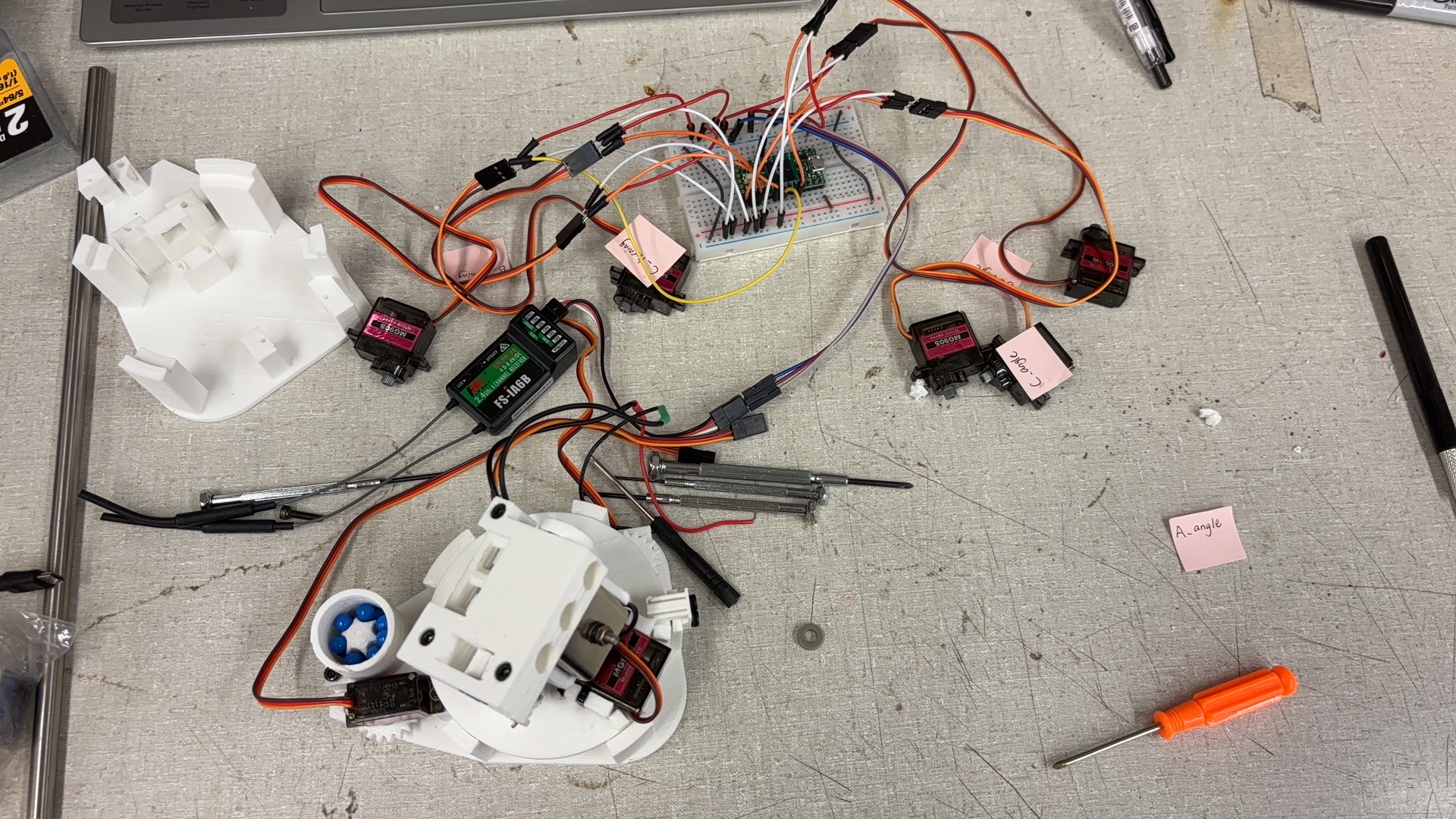

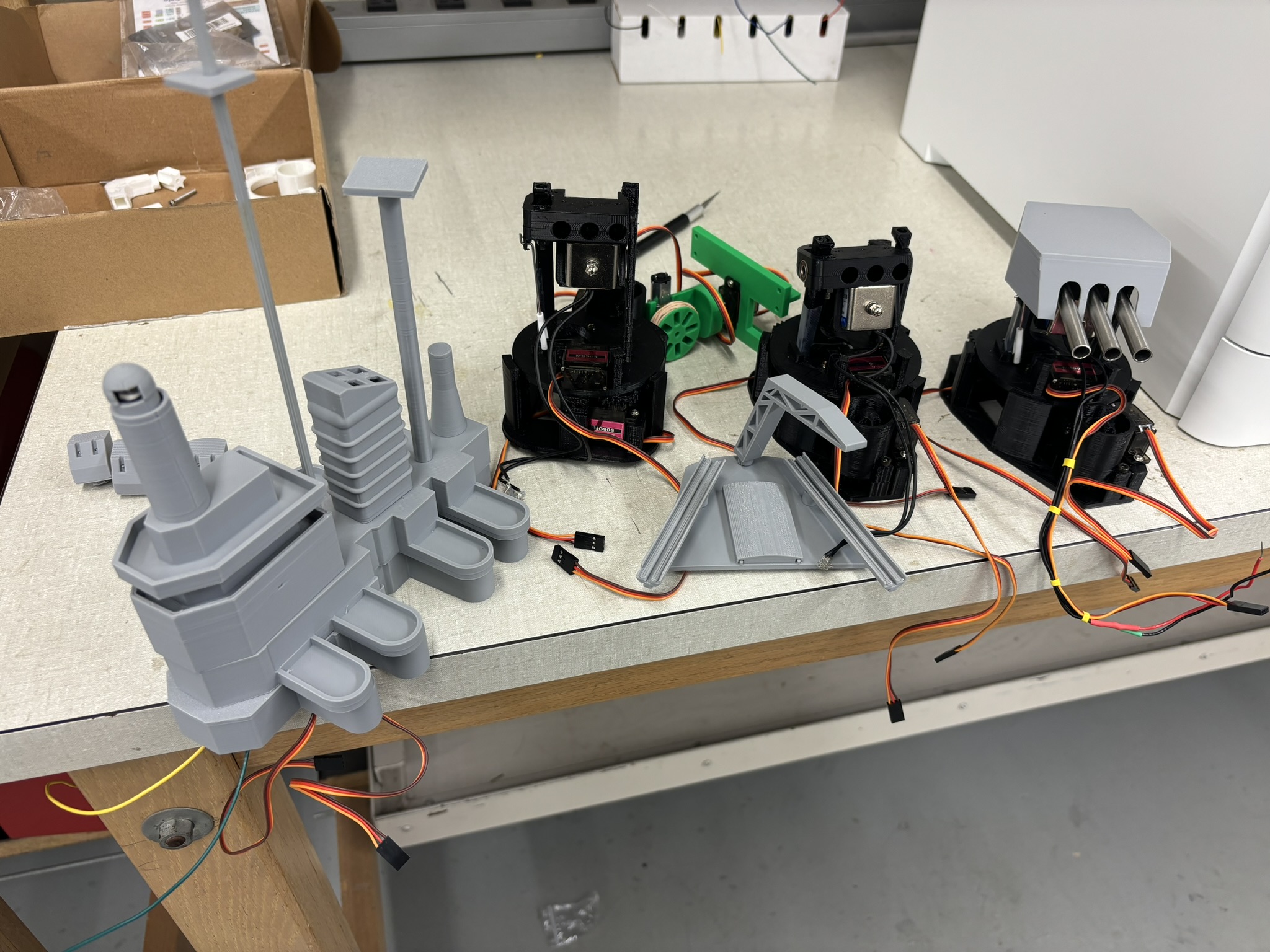

All designs you see on this page were the final designs that had been iterated from 20 to 70 times. It’s not practical for me to list all versions.

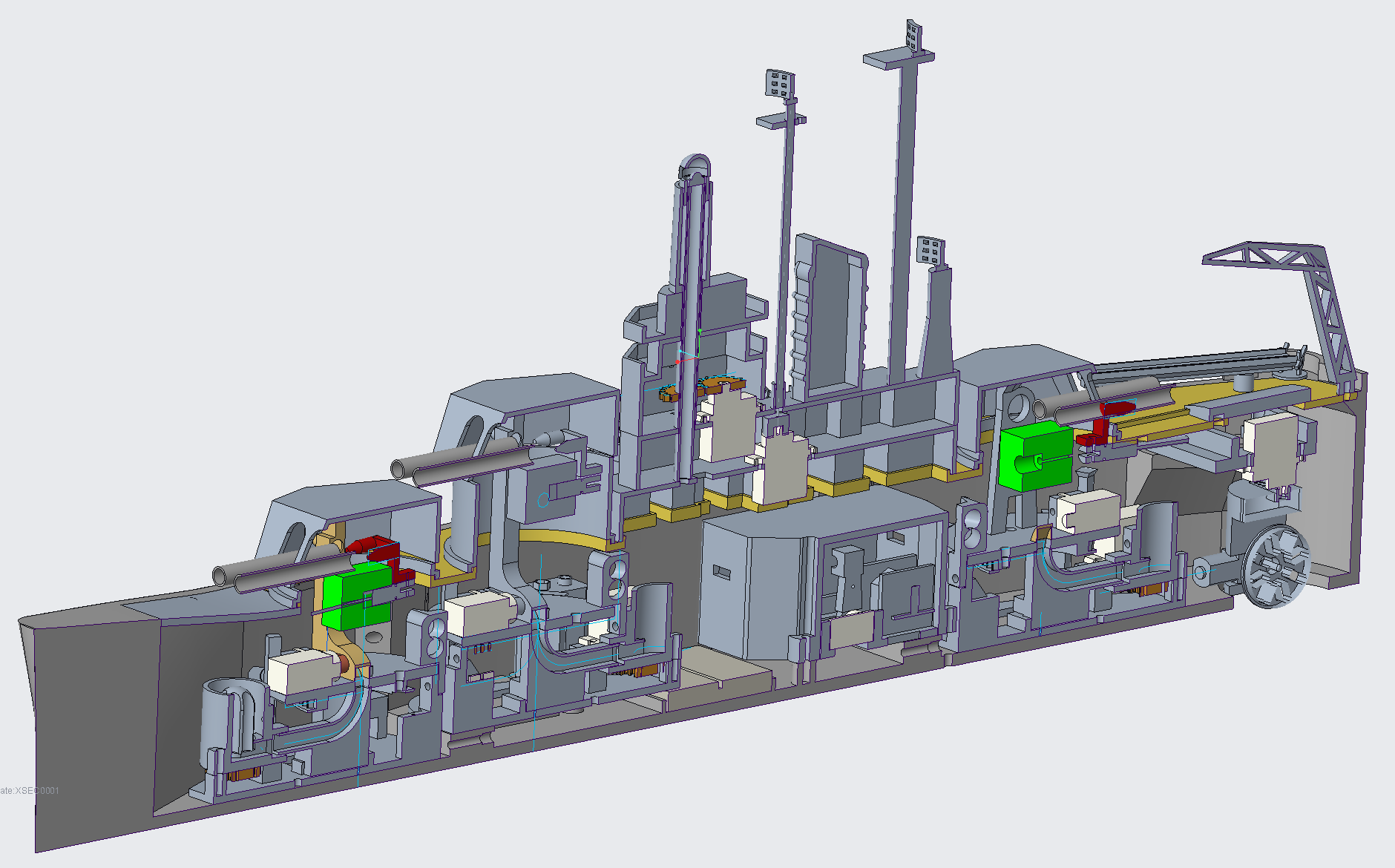

1. Hardware

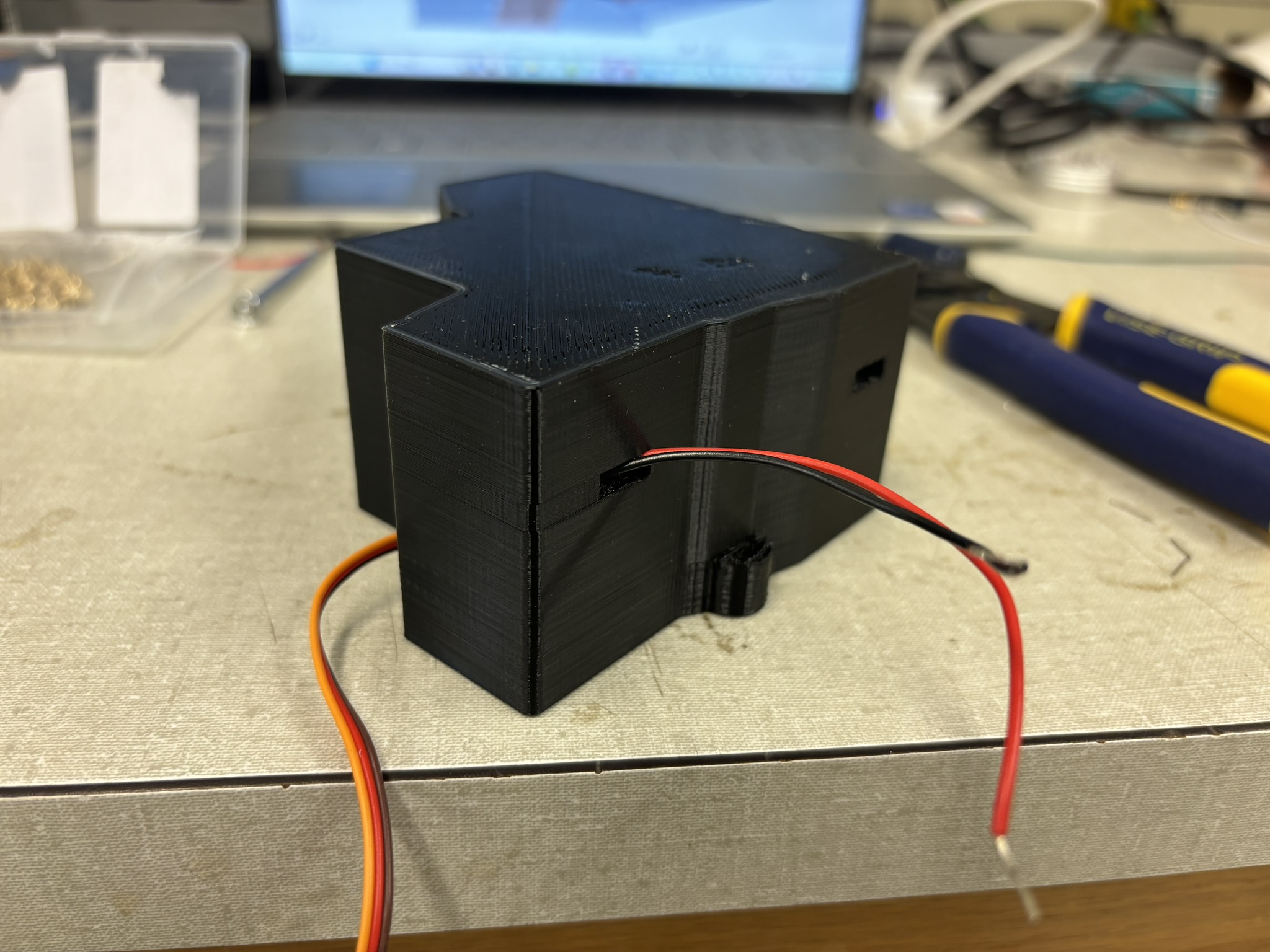

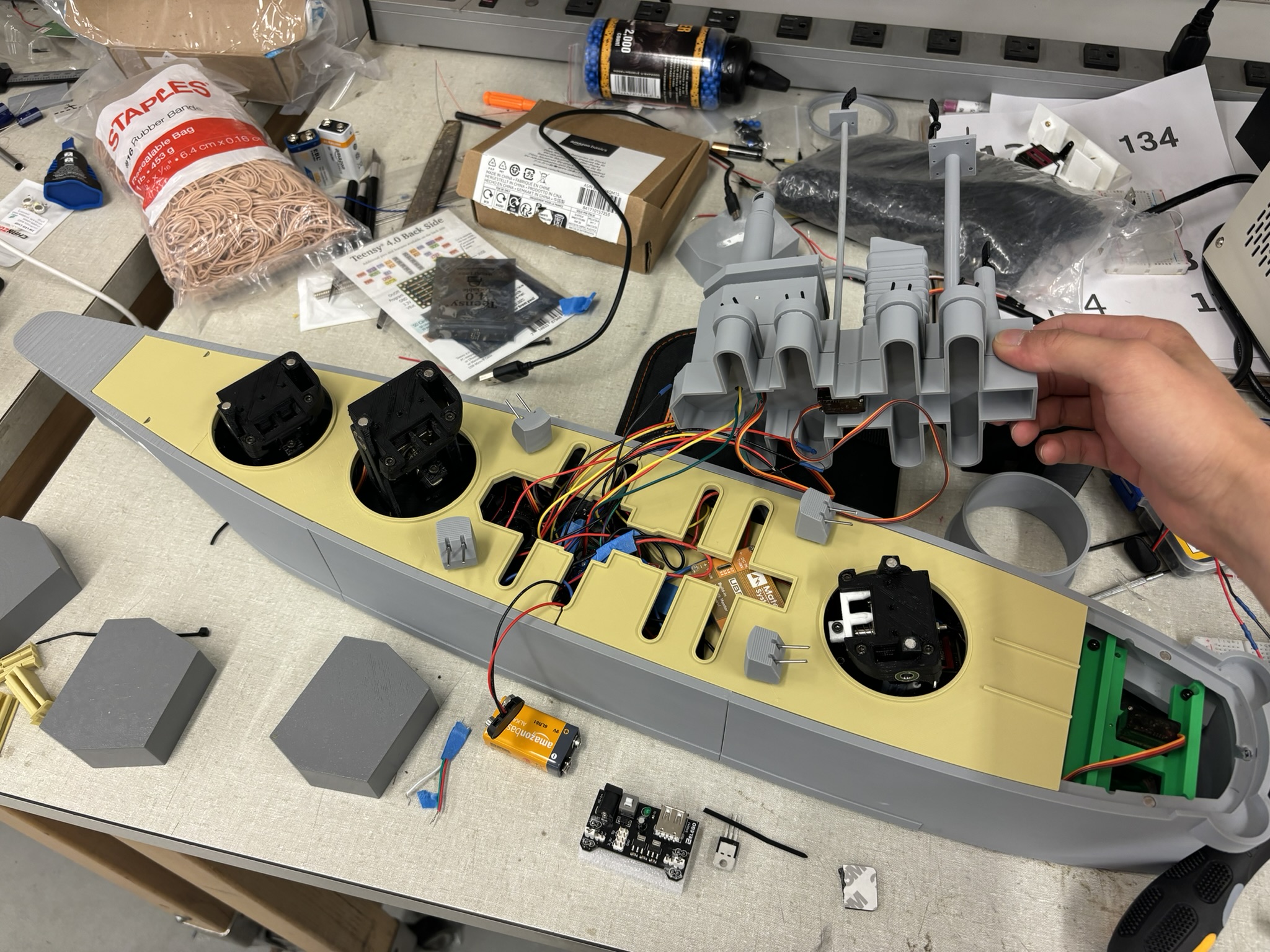

All hardware difficulties came from the size limit. We have to make the parts as small as possible, but the servo we used were still very large, which made the design process even harder. We started with the turret. If we design the turret with a comfortable size, the whole ship would be about 1.5 meters long with the right scale. It was a hard decision to break the scale.

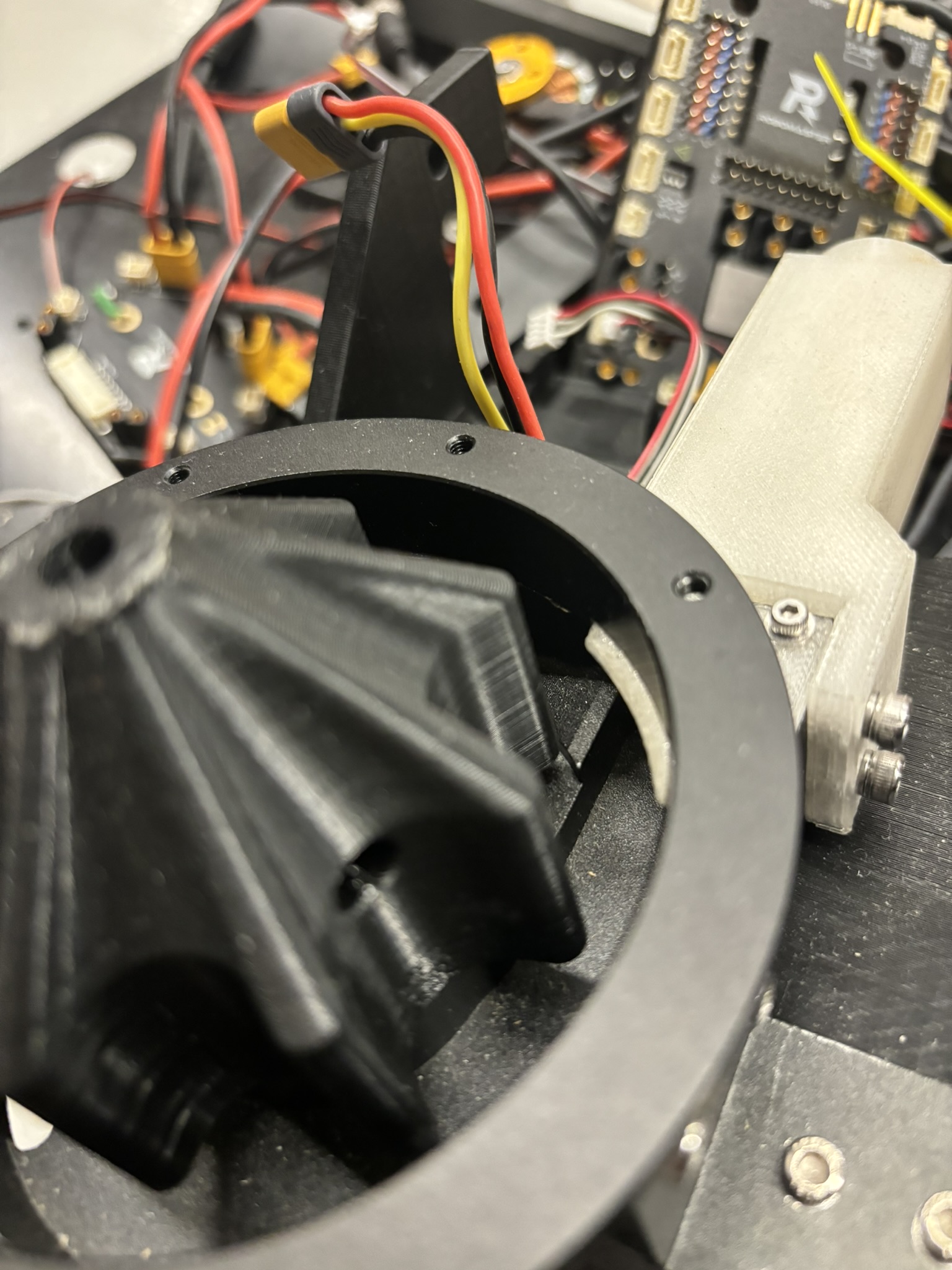

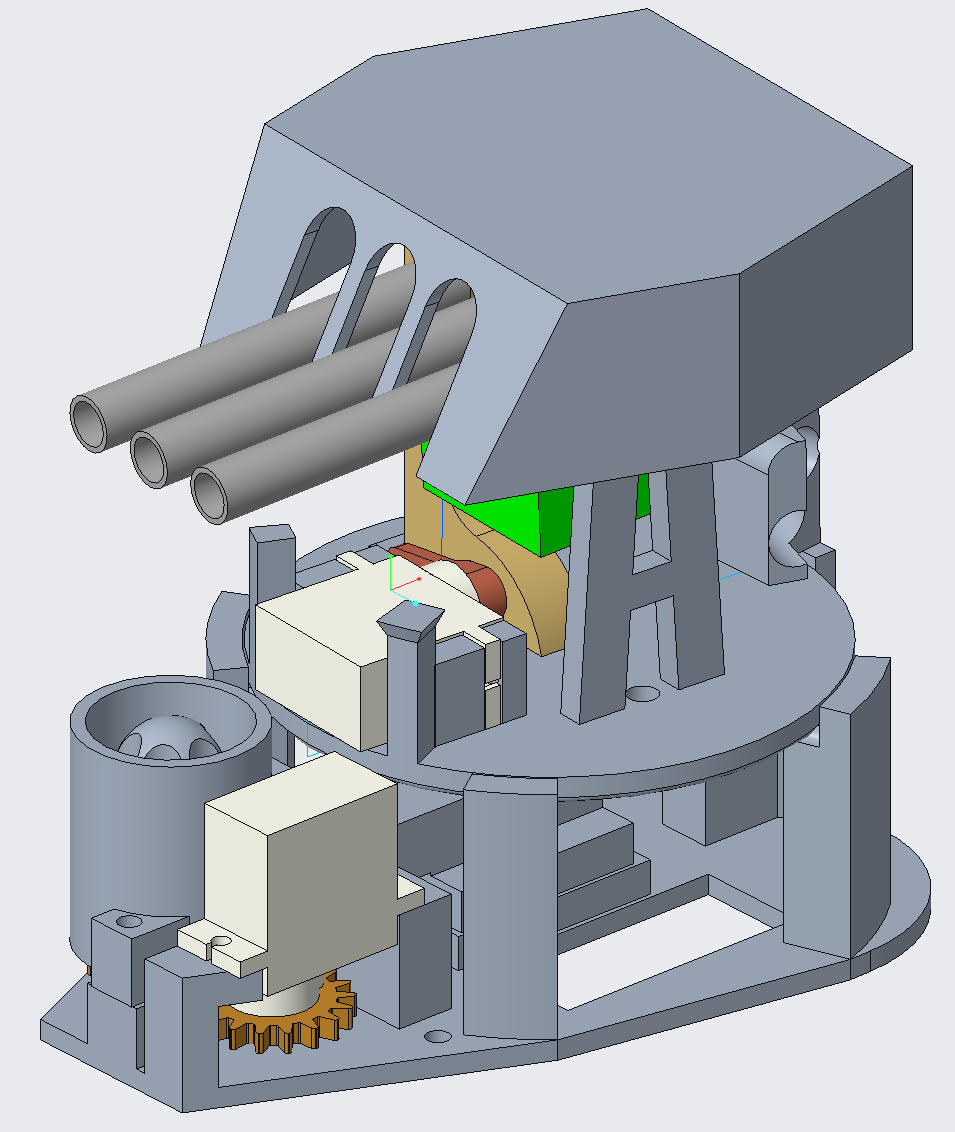

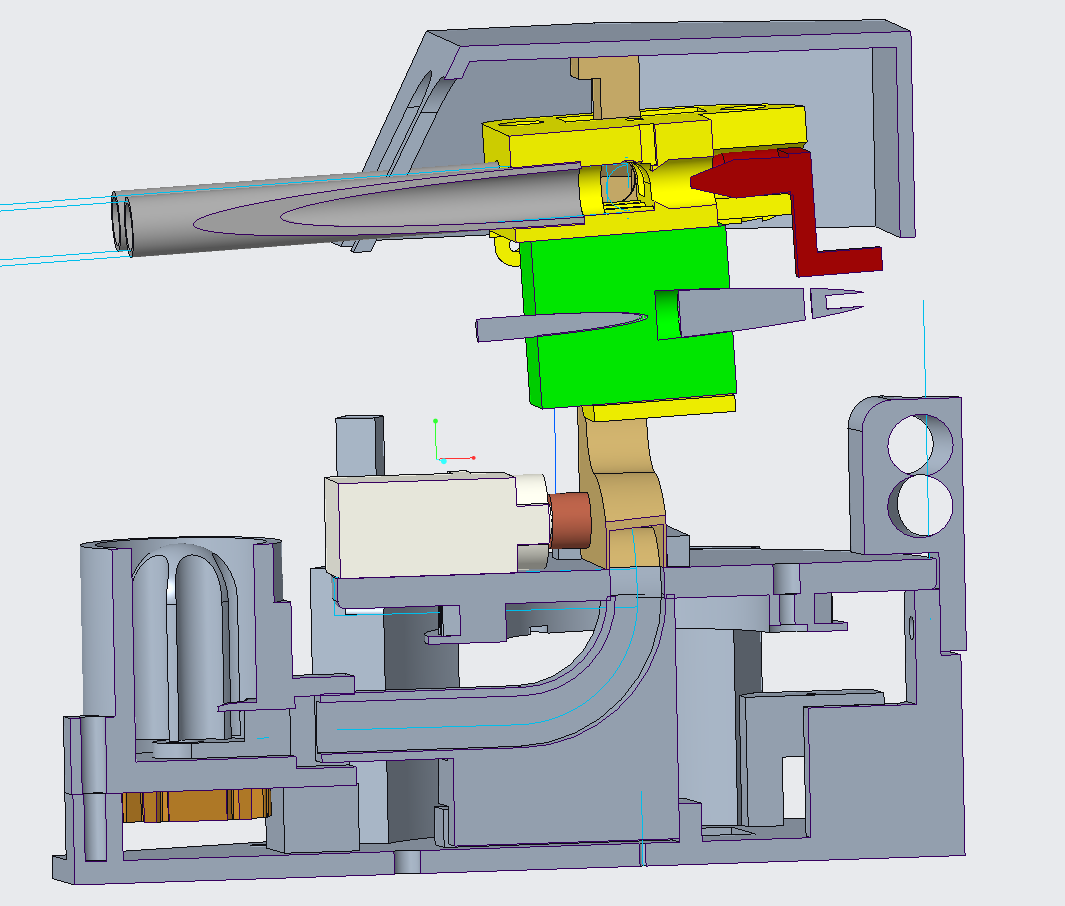

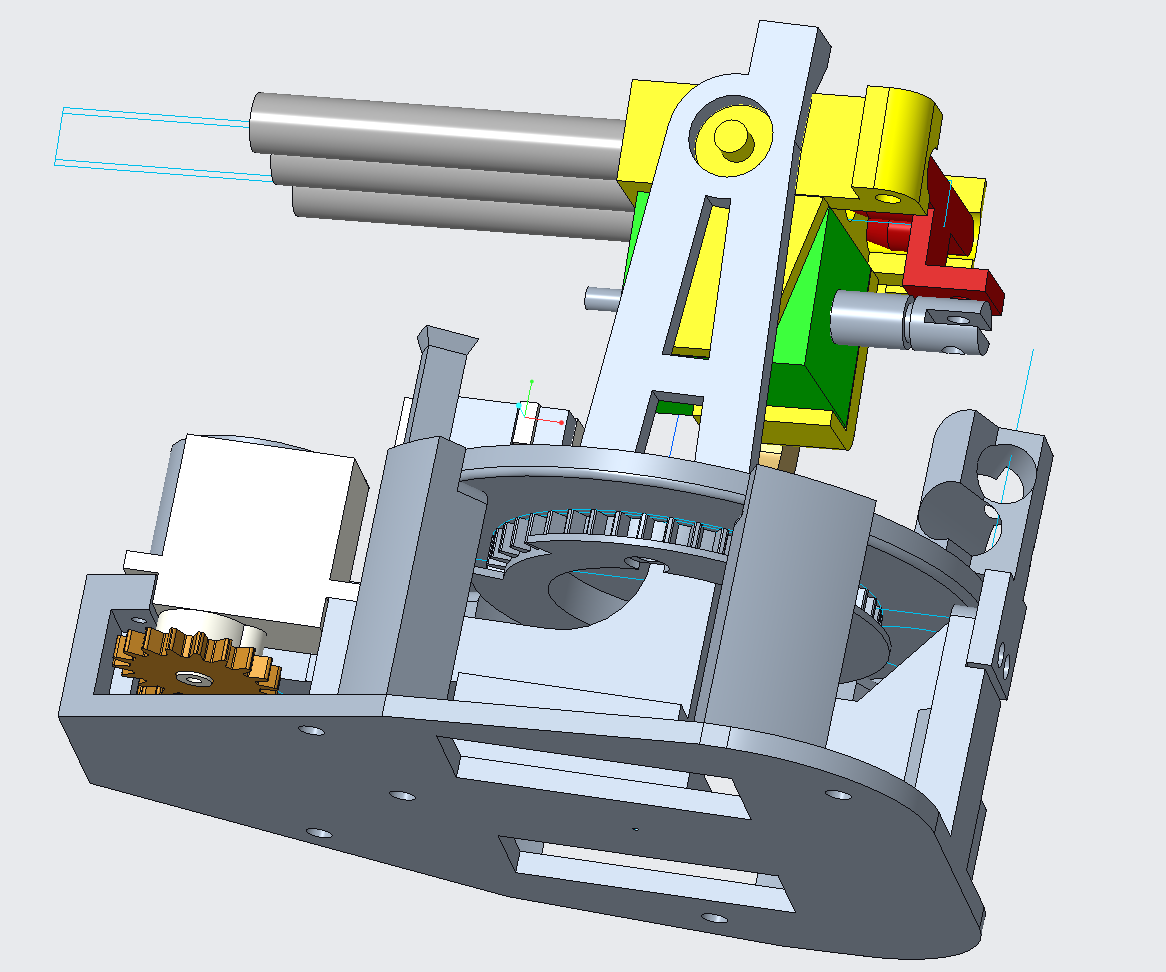

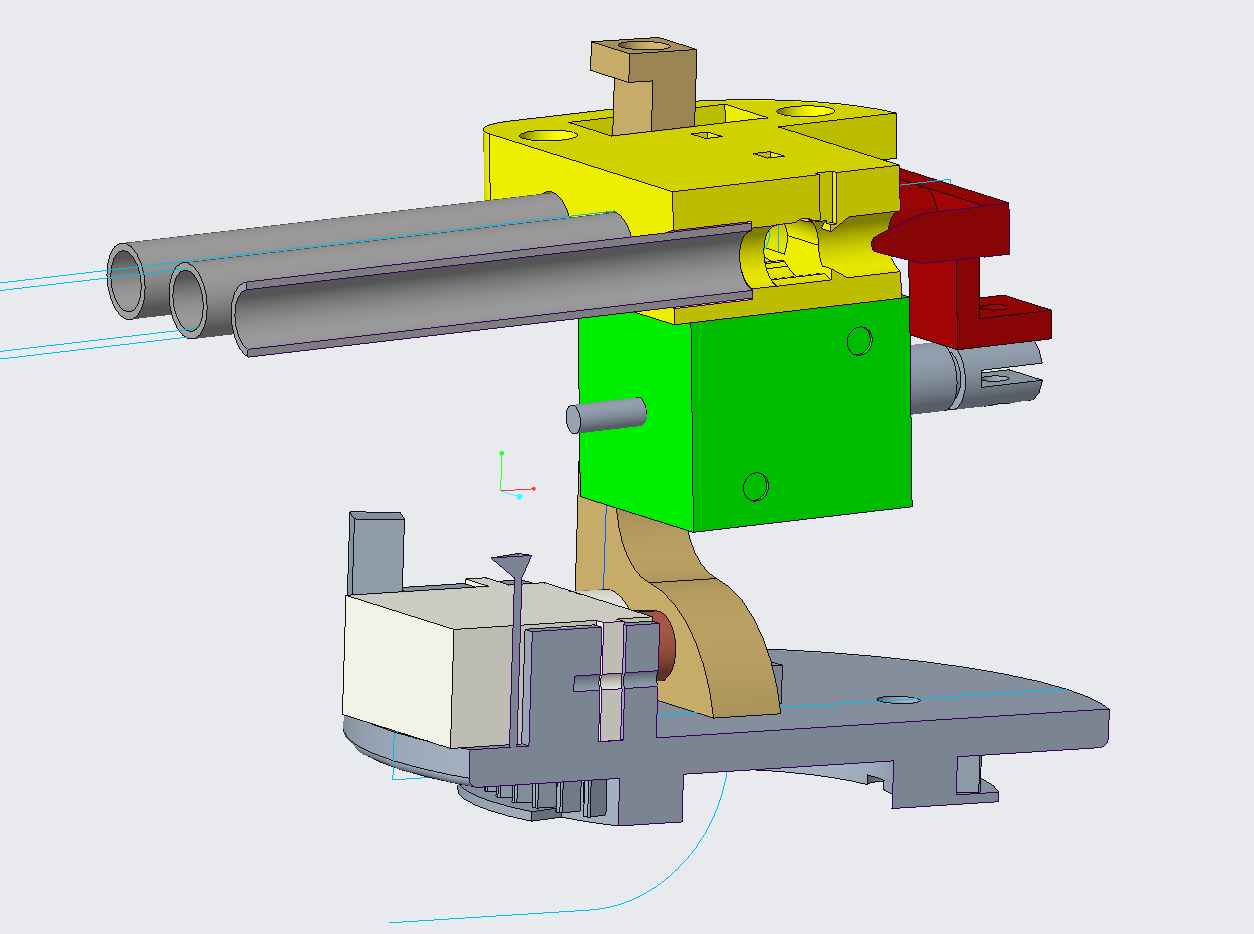

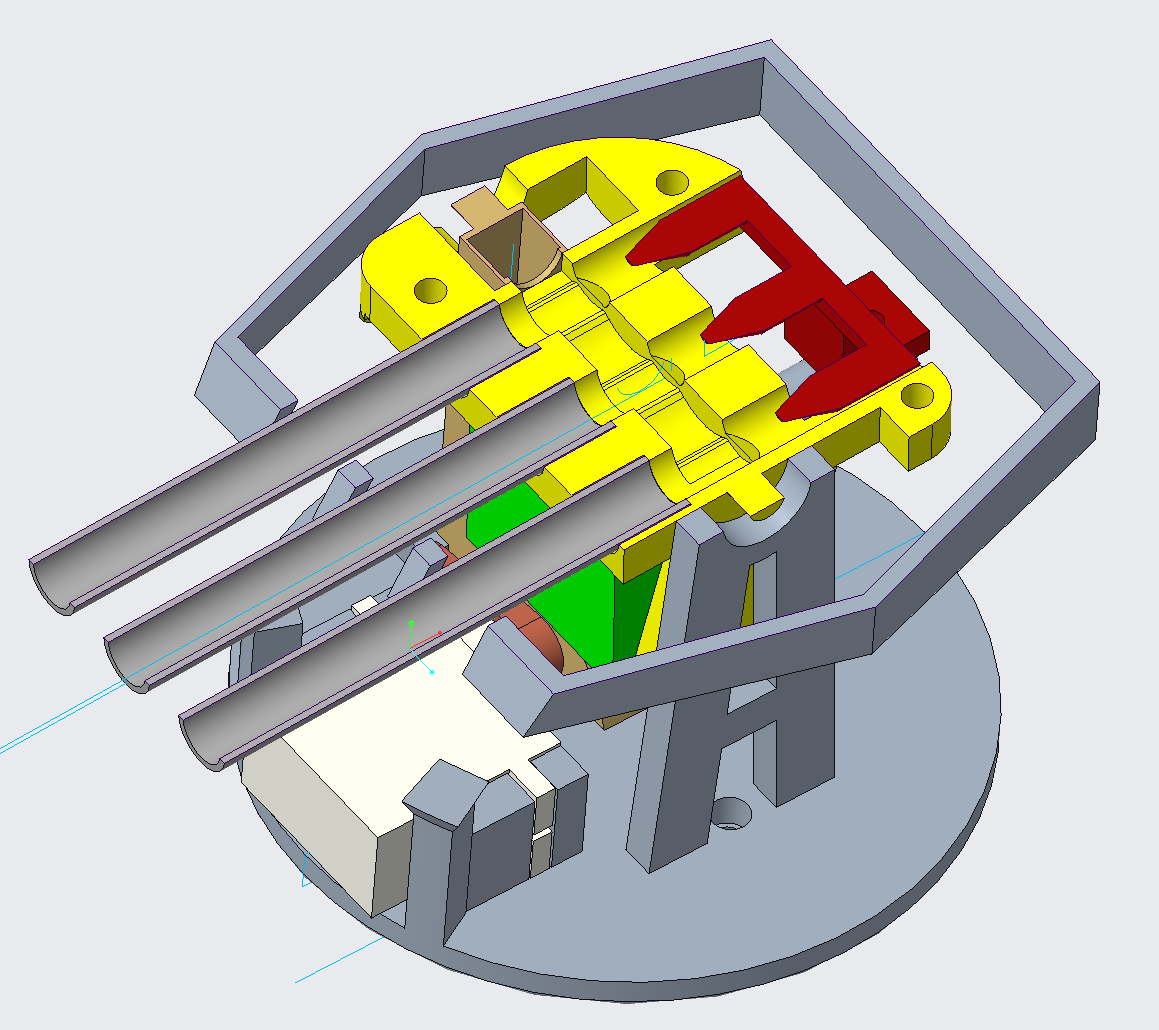

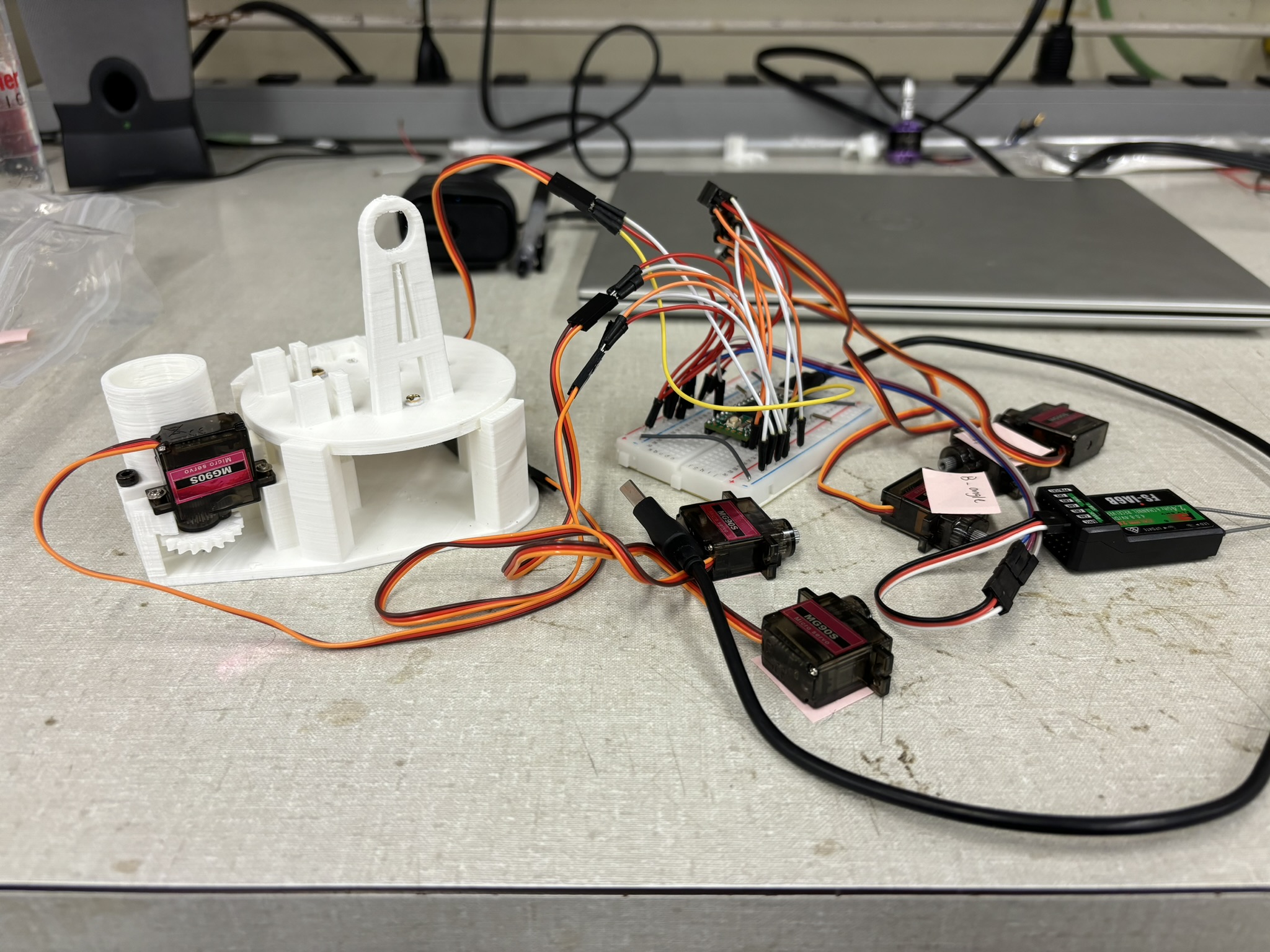

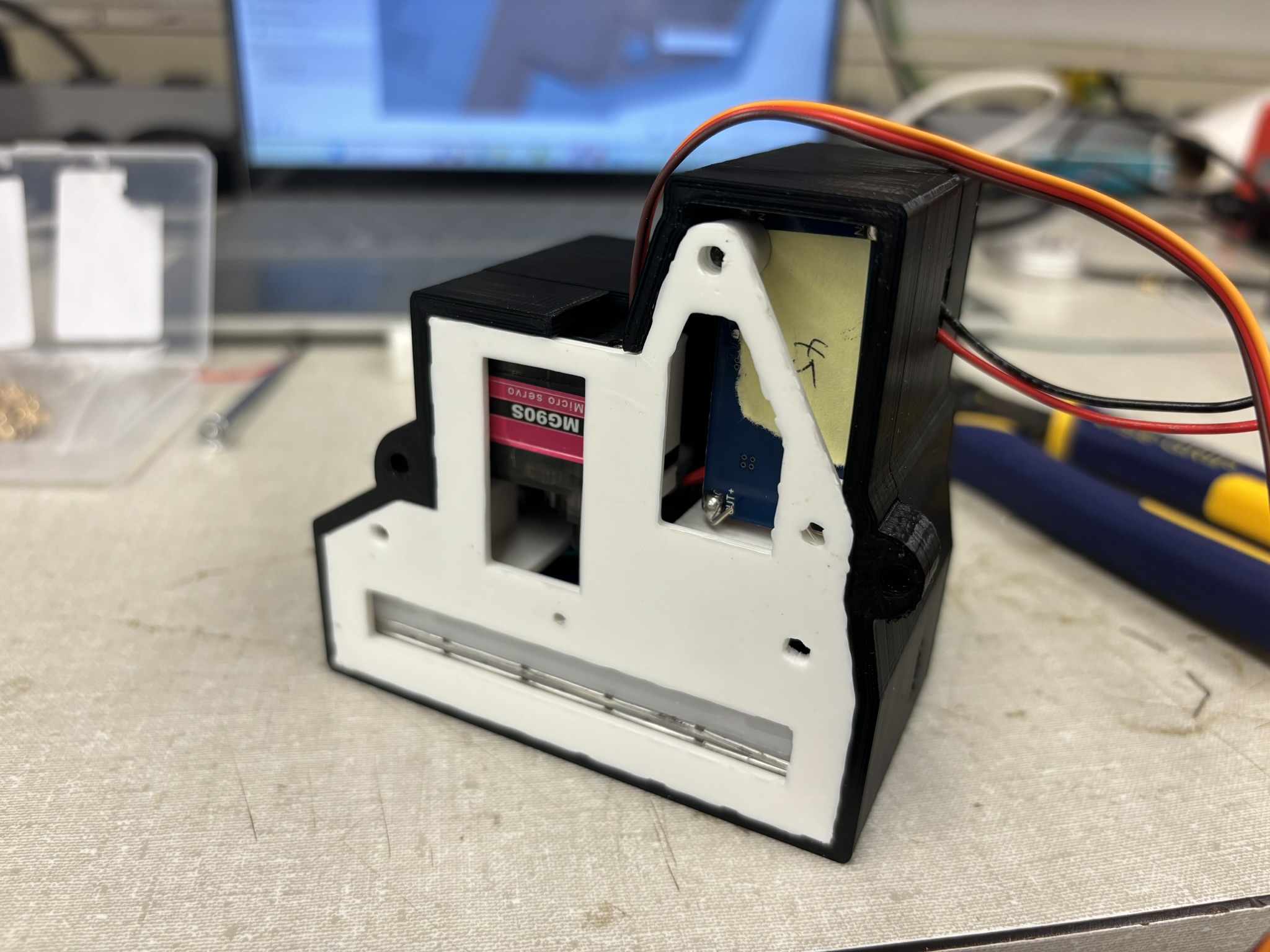

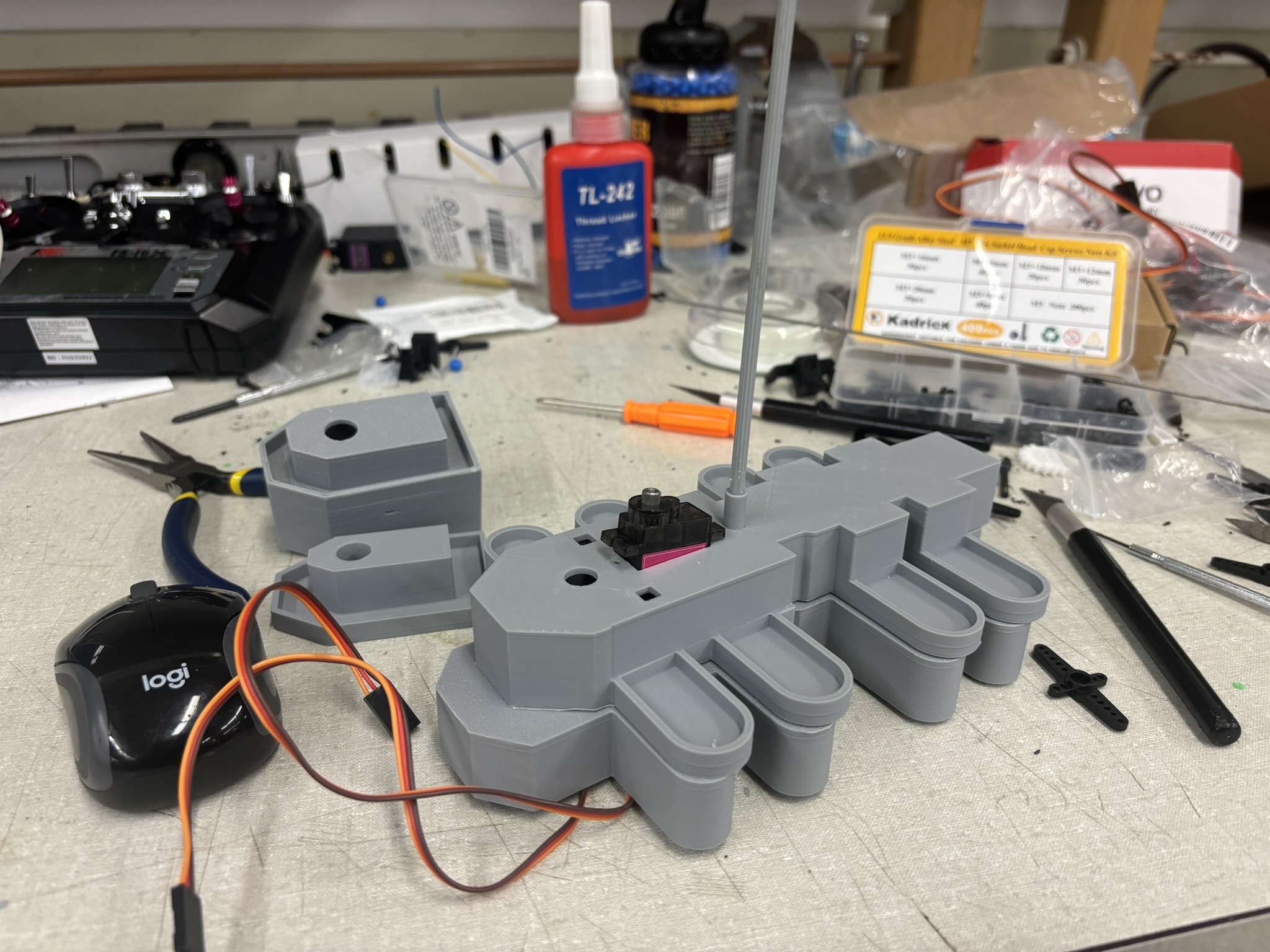

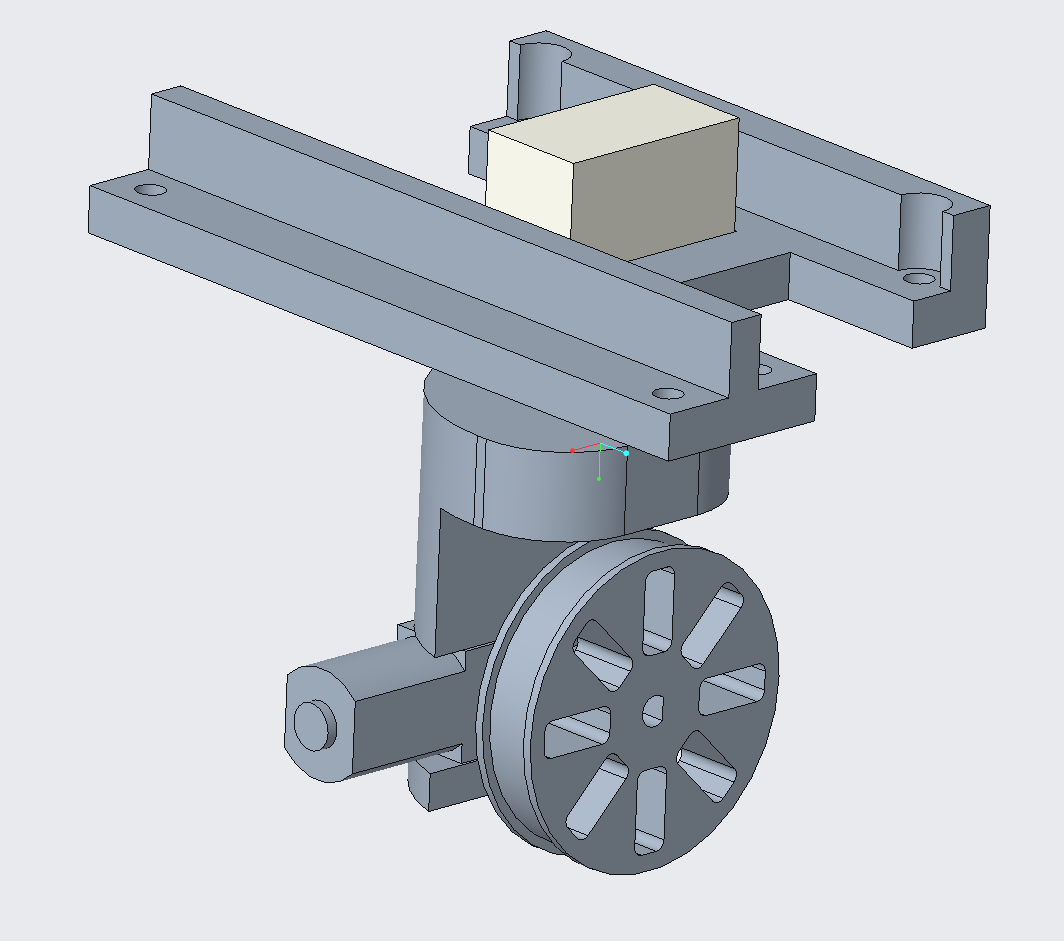

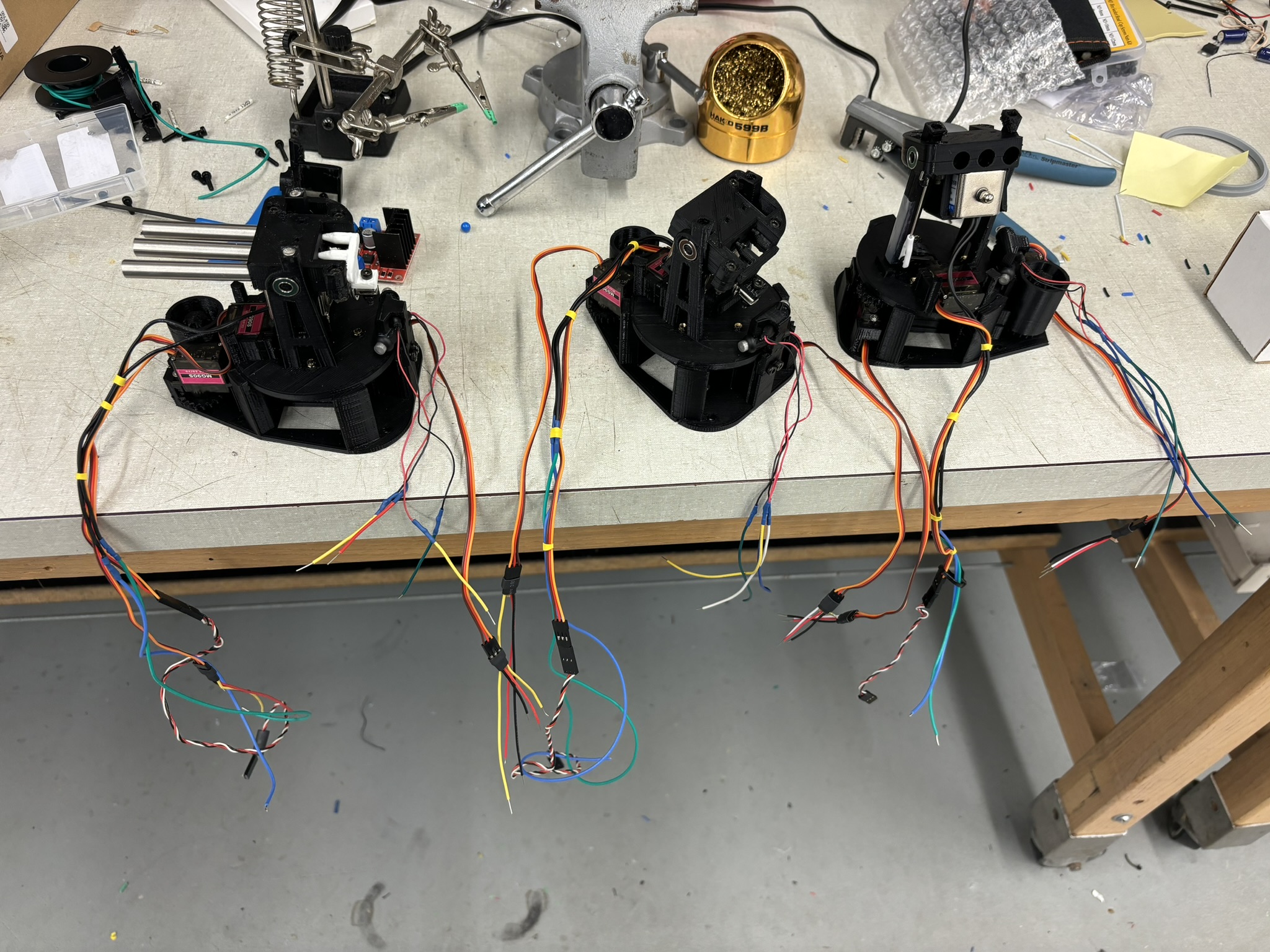

1.1 Turret

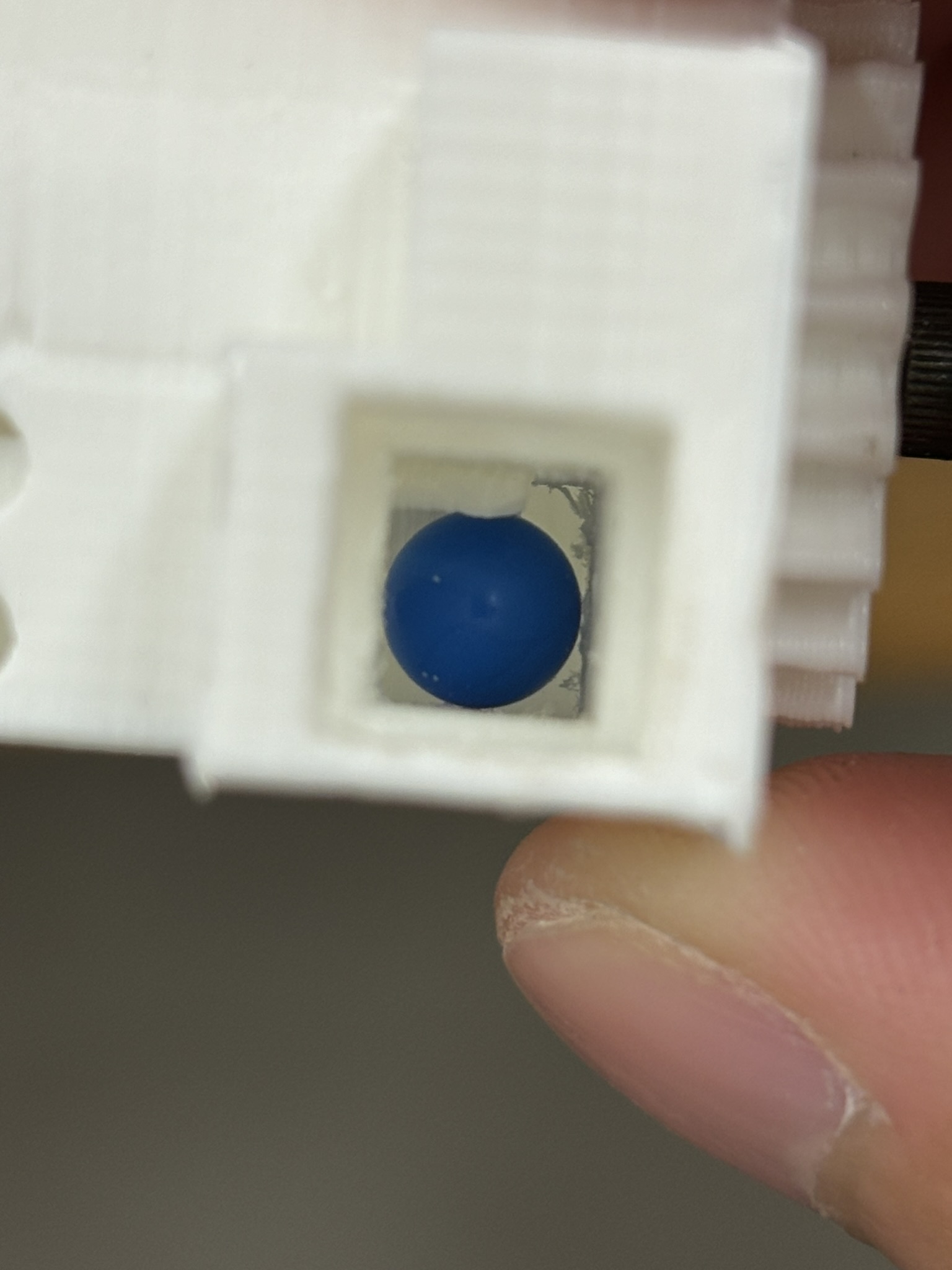

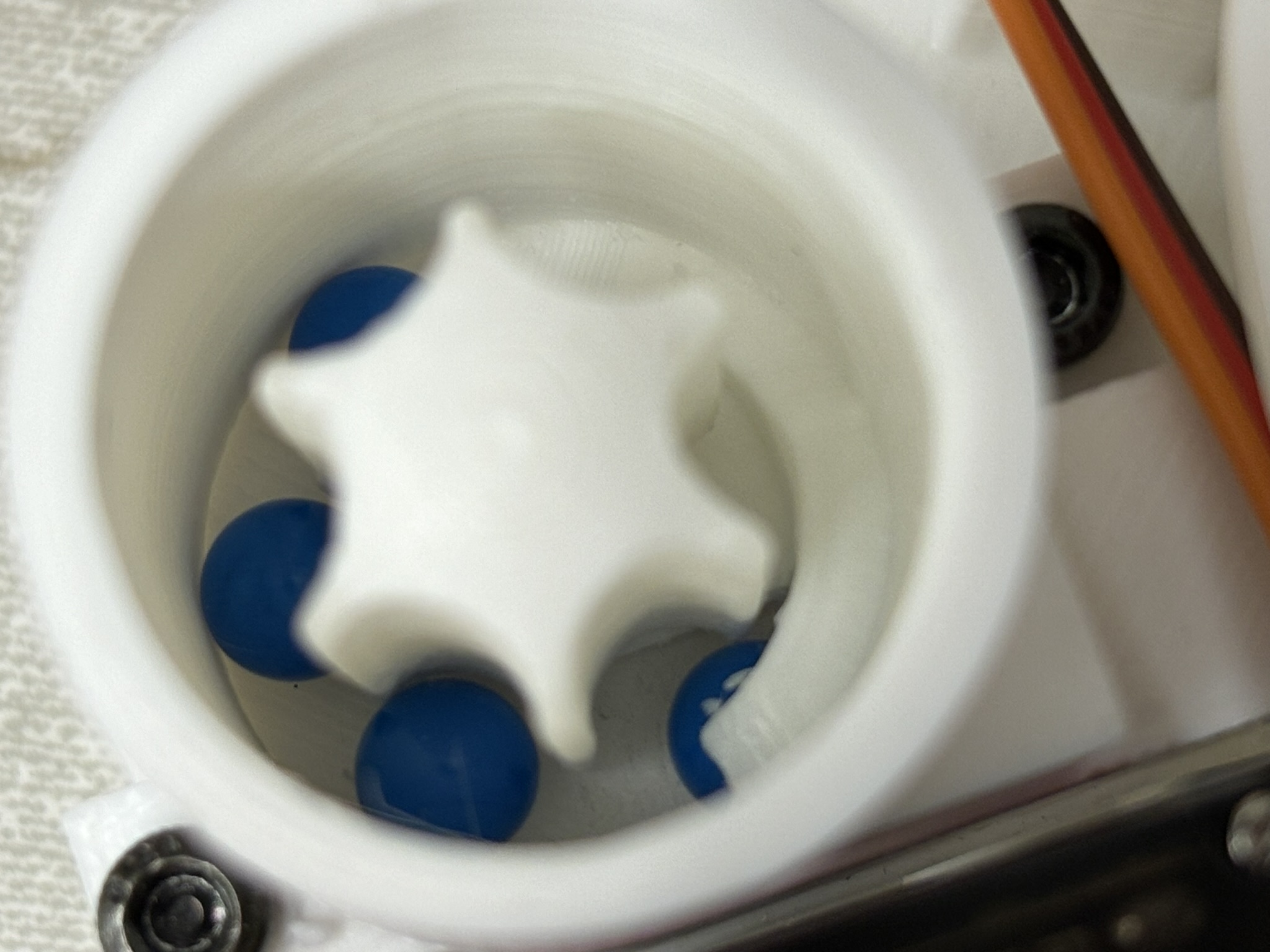

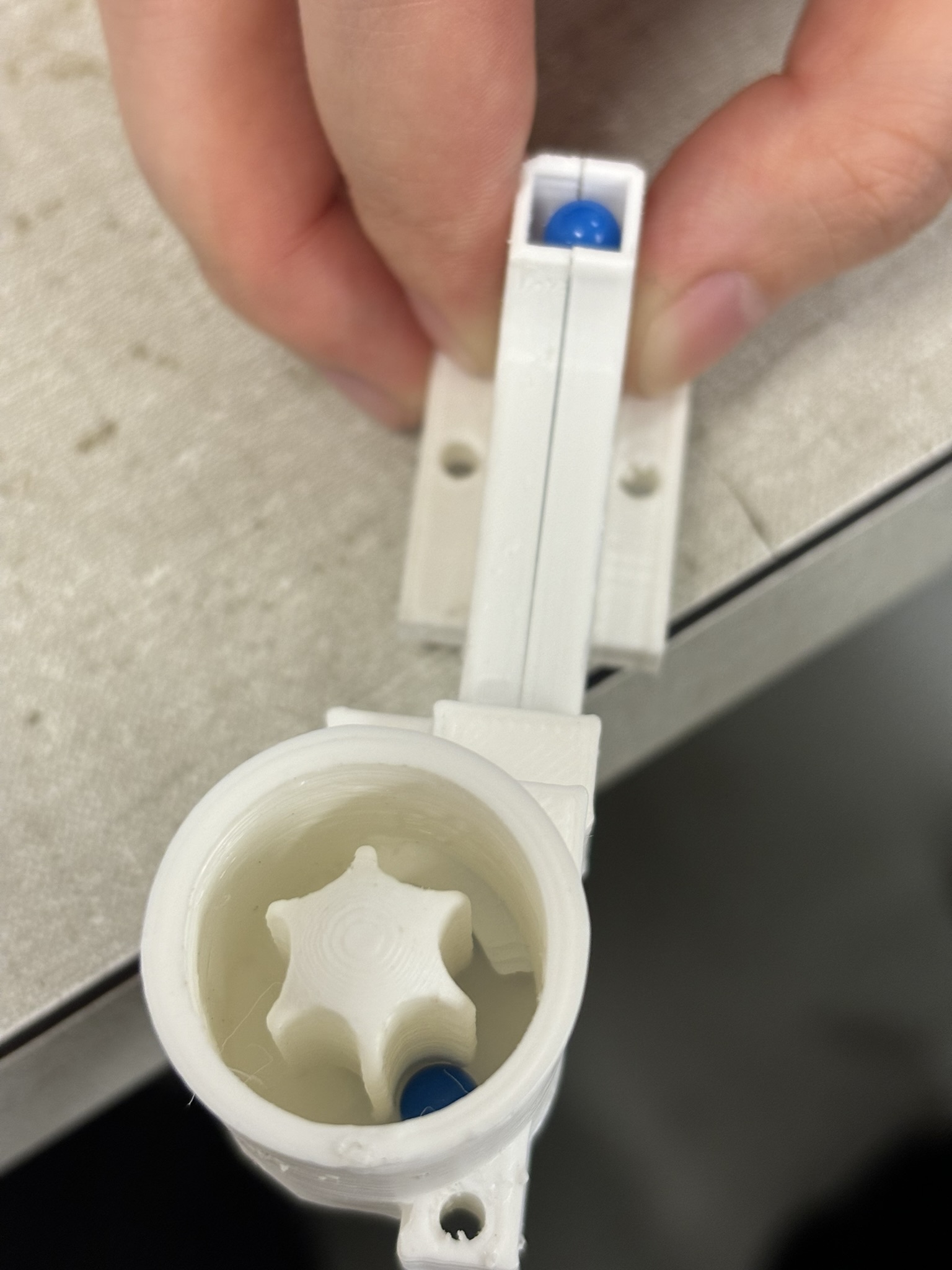

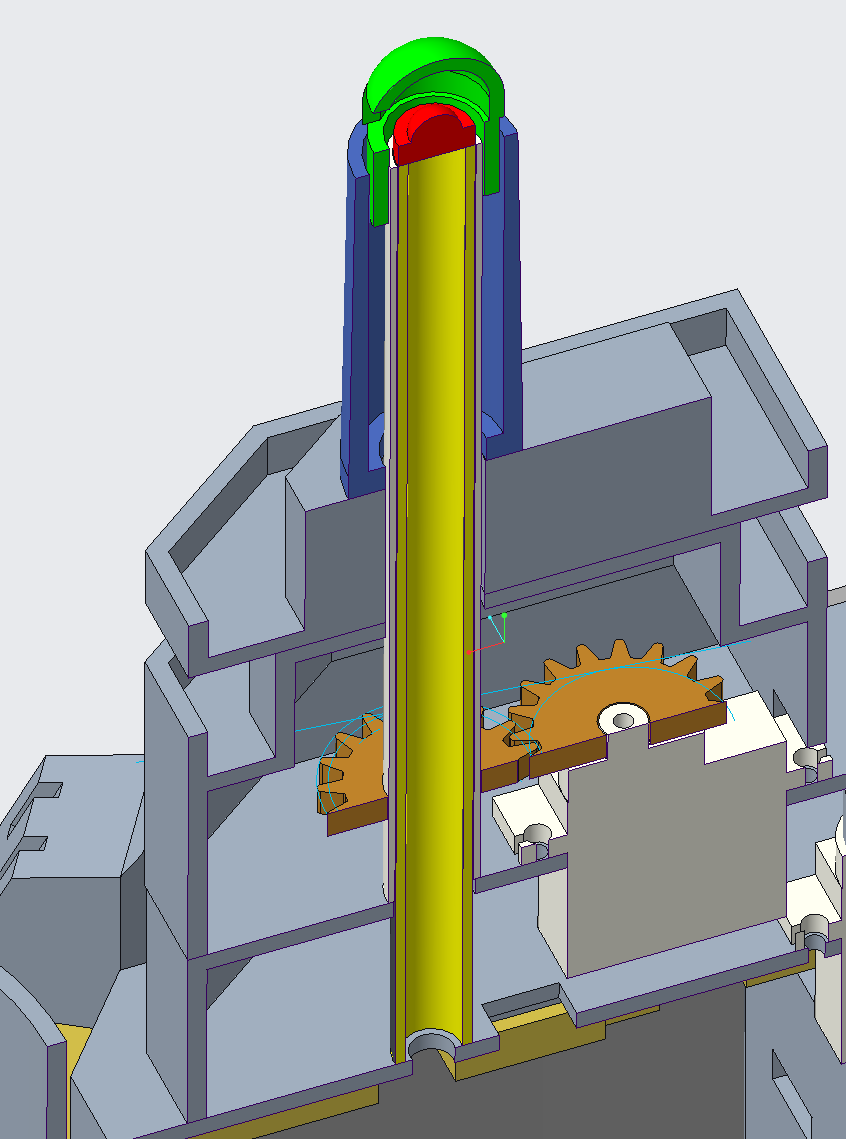

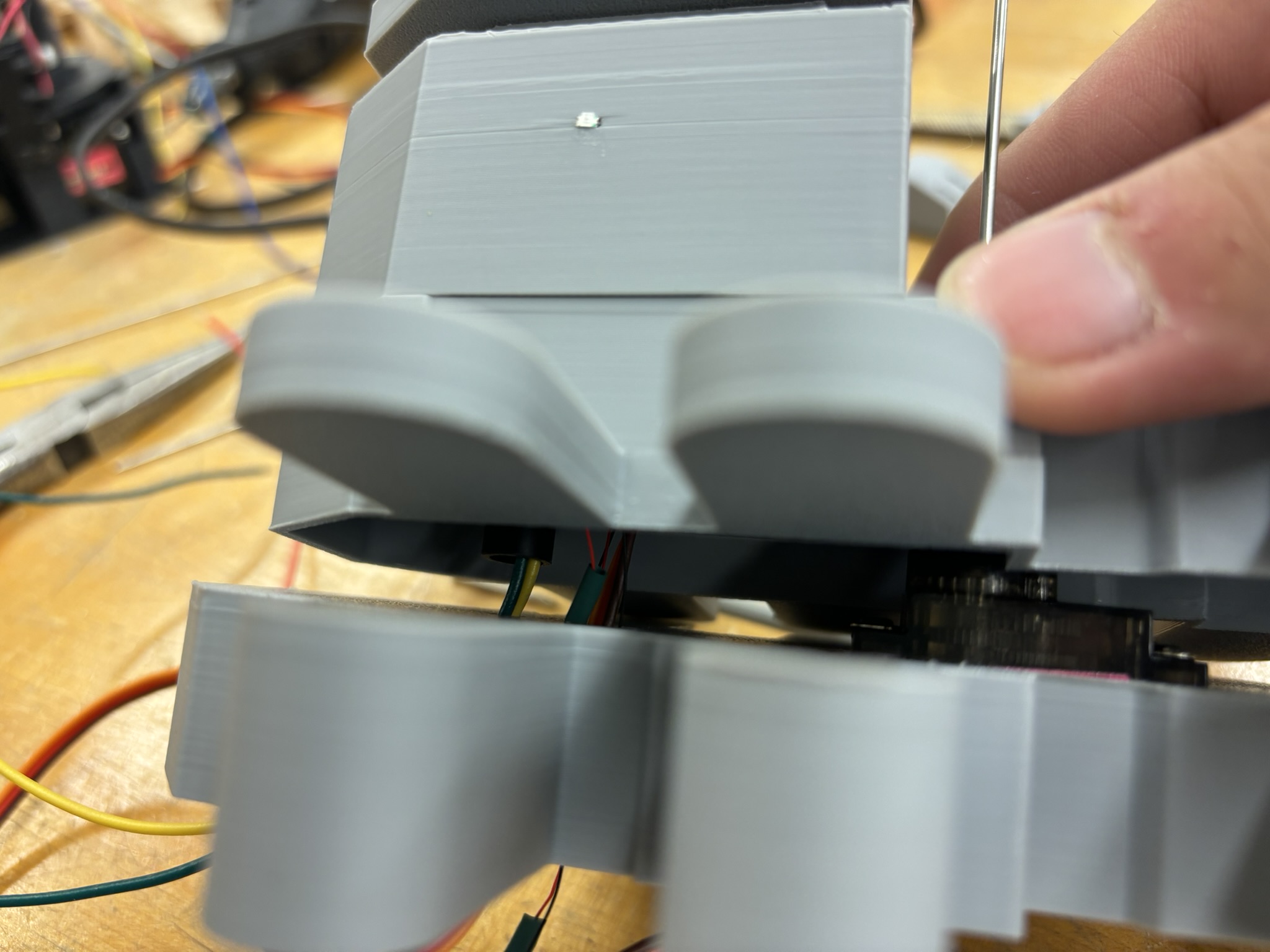

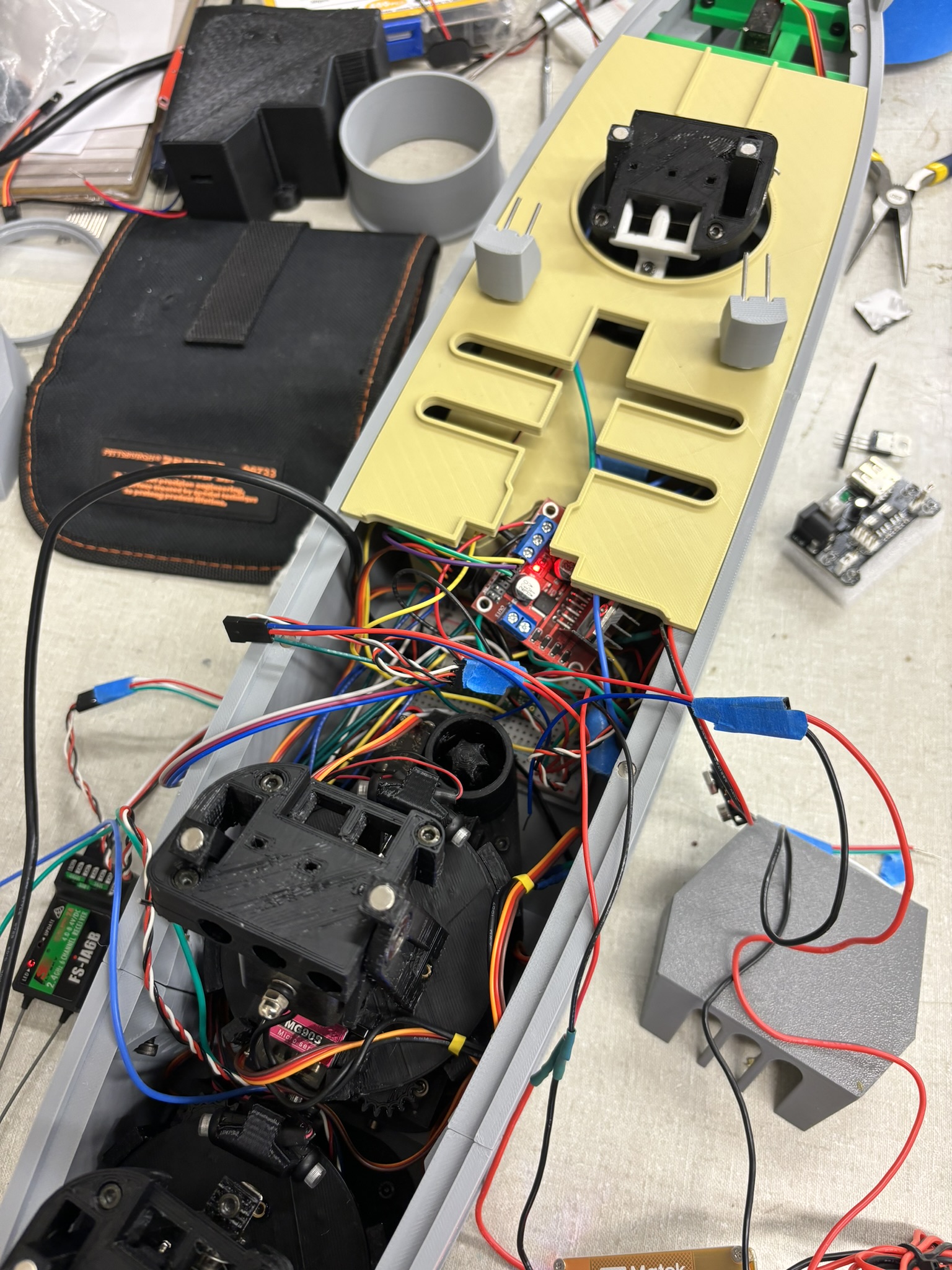

A turret contains a turret base and a rotating part. The turret base has a pump, which is learned from Robotmaster. The tubes are aligned with the rotating axis, so the 6mm airsoft bullet can be supplied at any turret angle. The bullets are triggered by a solenoid. Turret took us the most of the time during the project, but there’s not much things to say. Just check out the pictures.

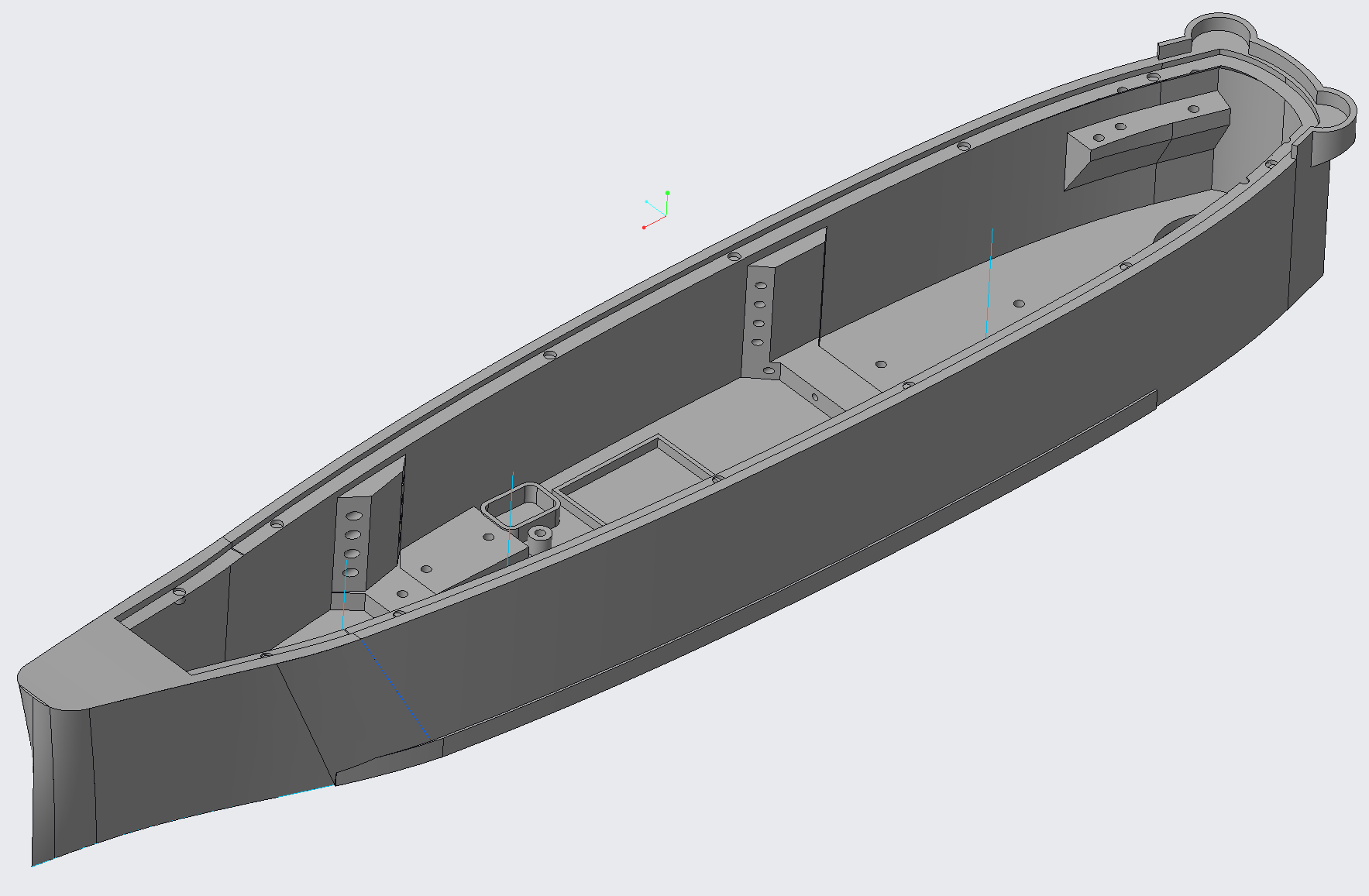

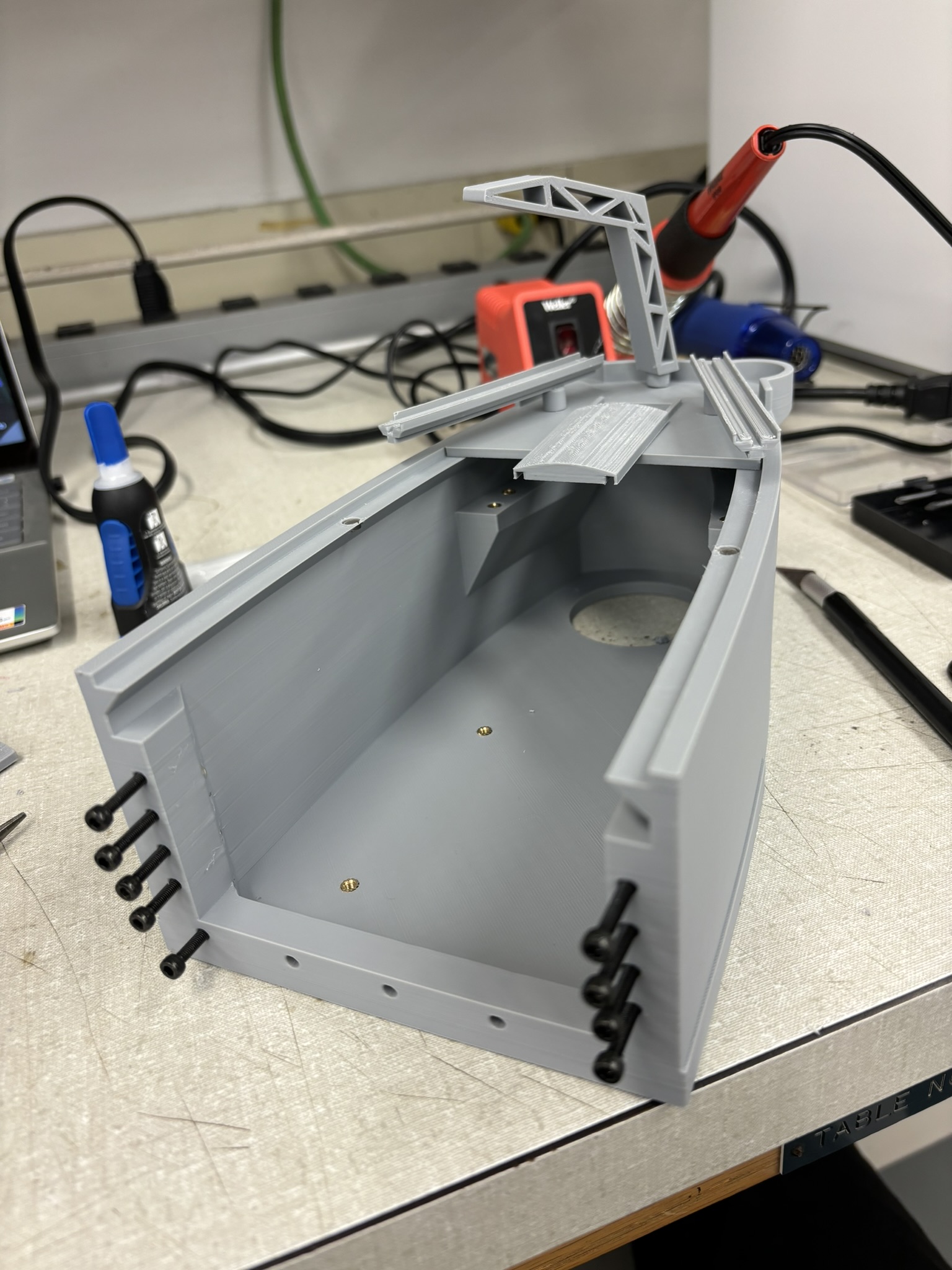

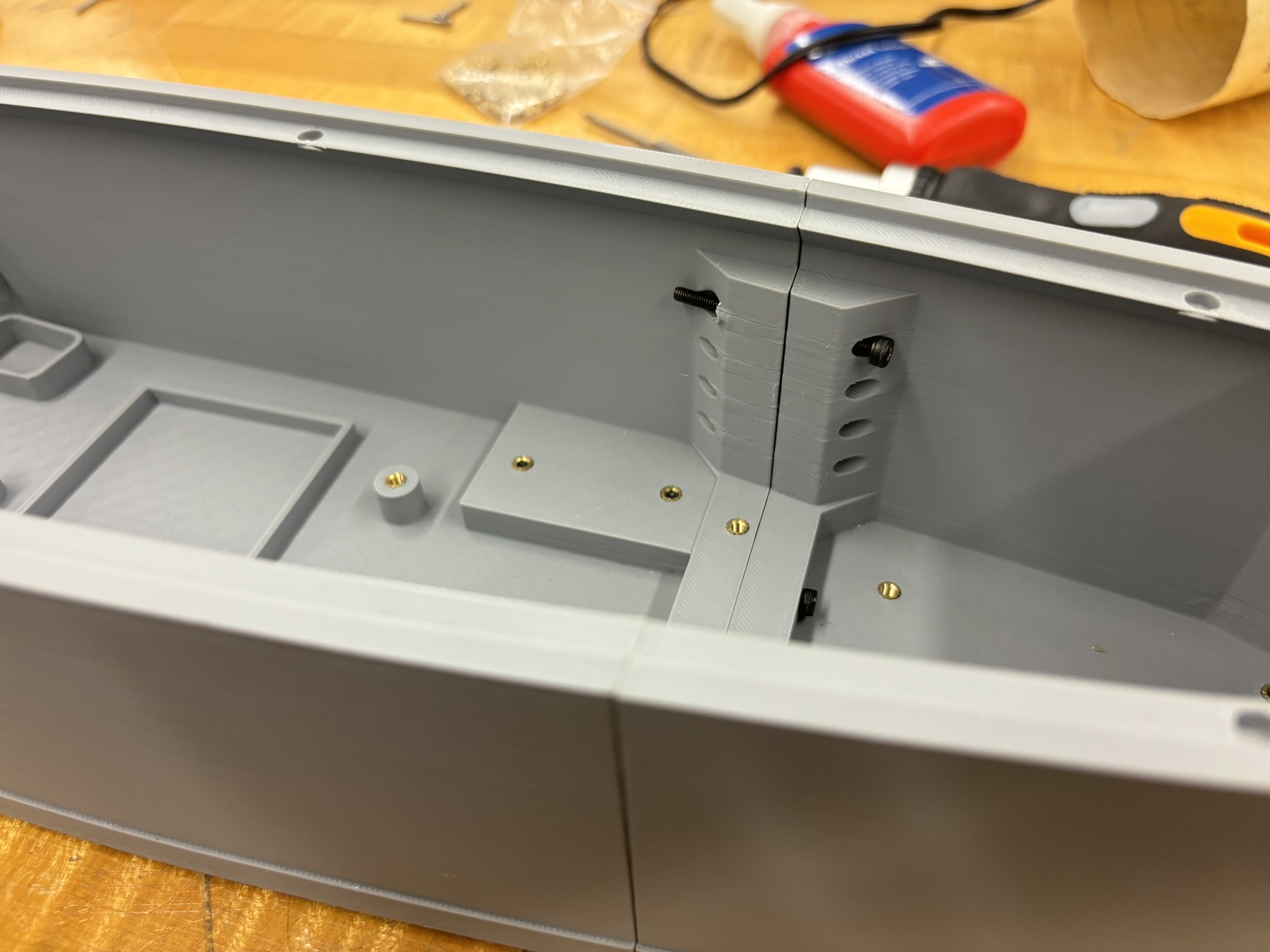

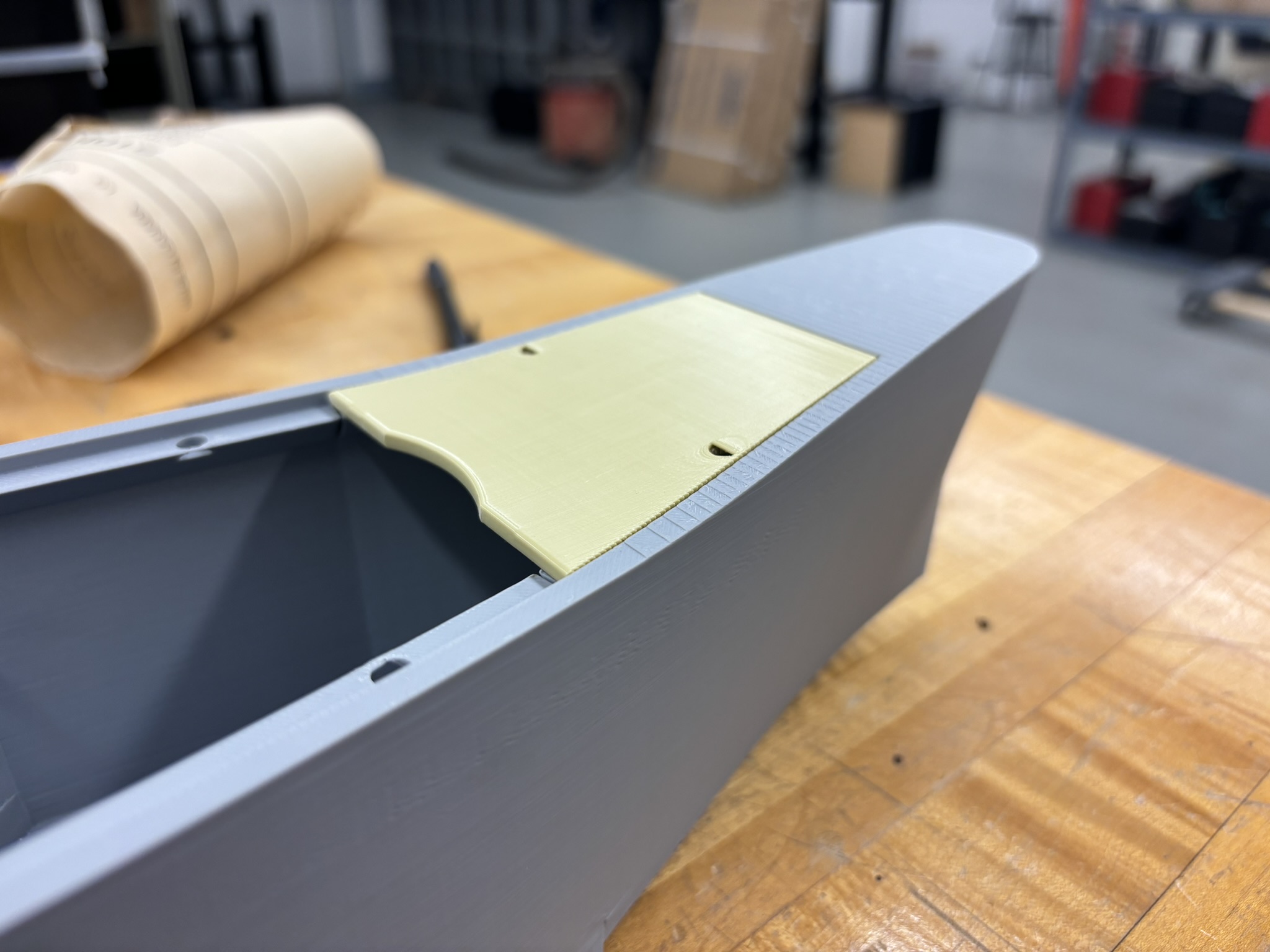

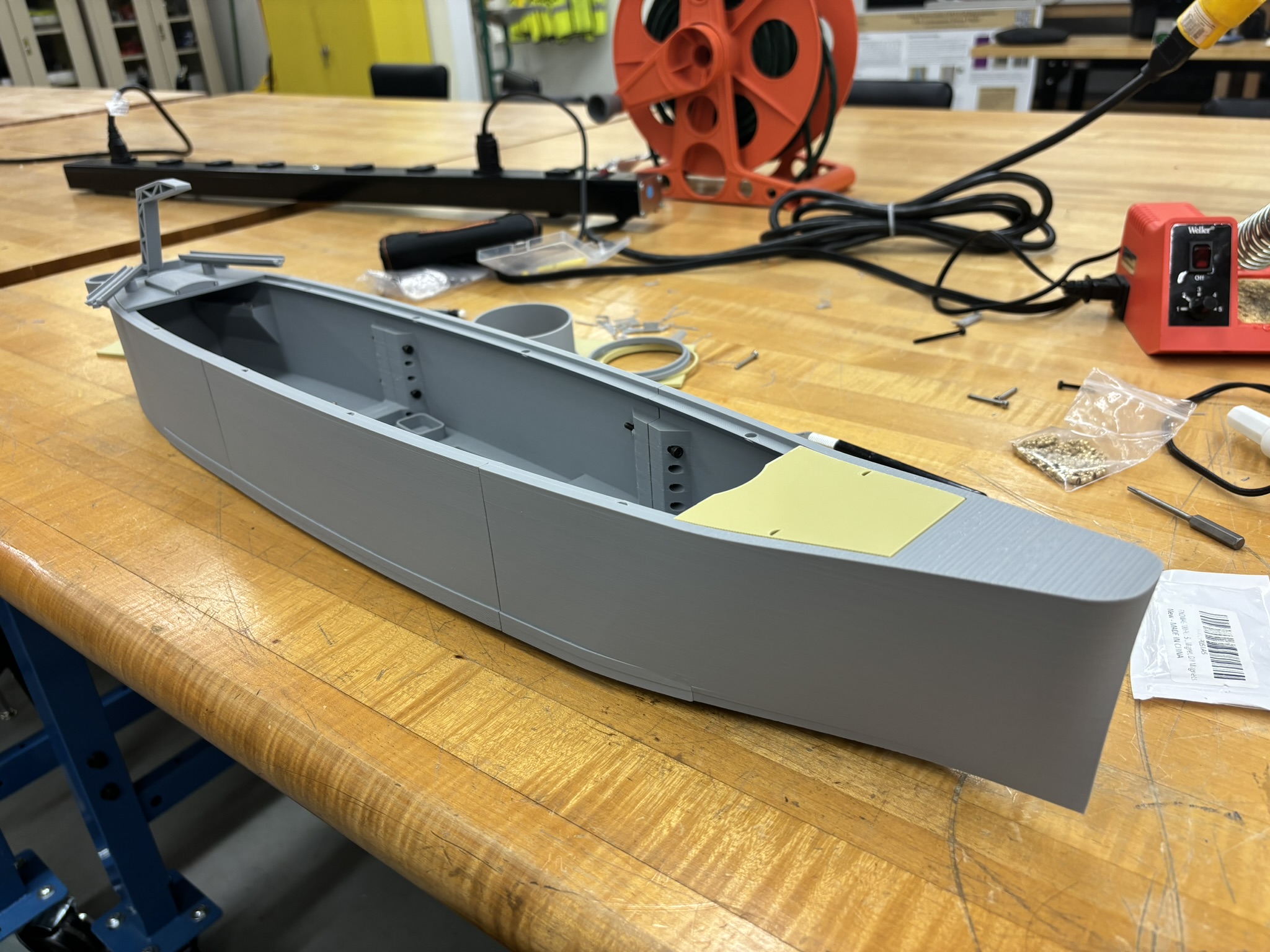

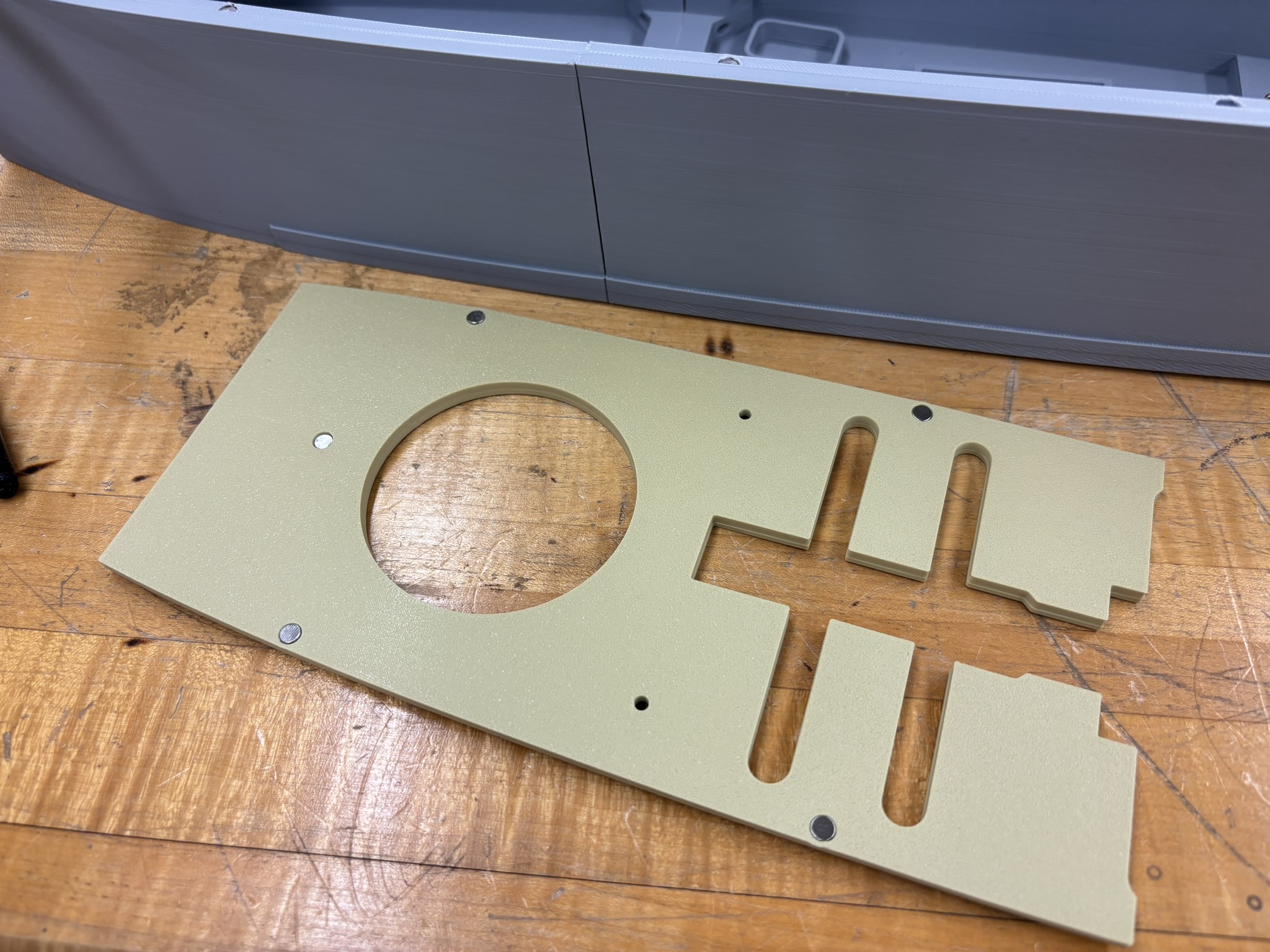

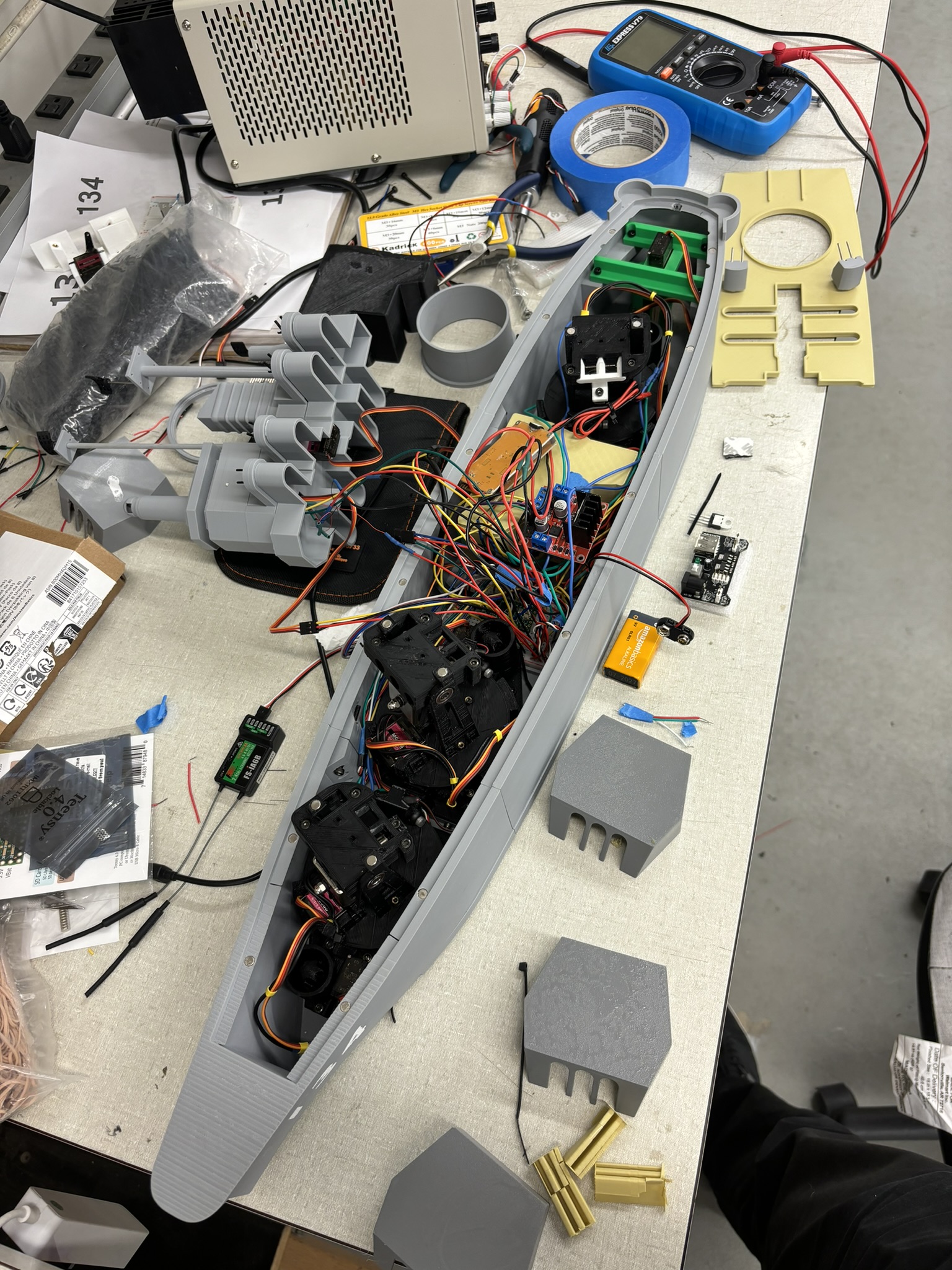

1.2 Ship hull

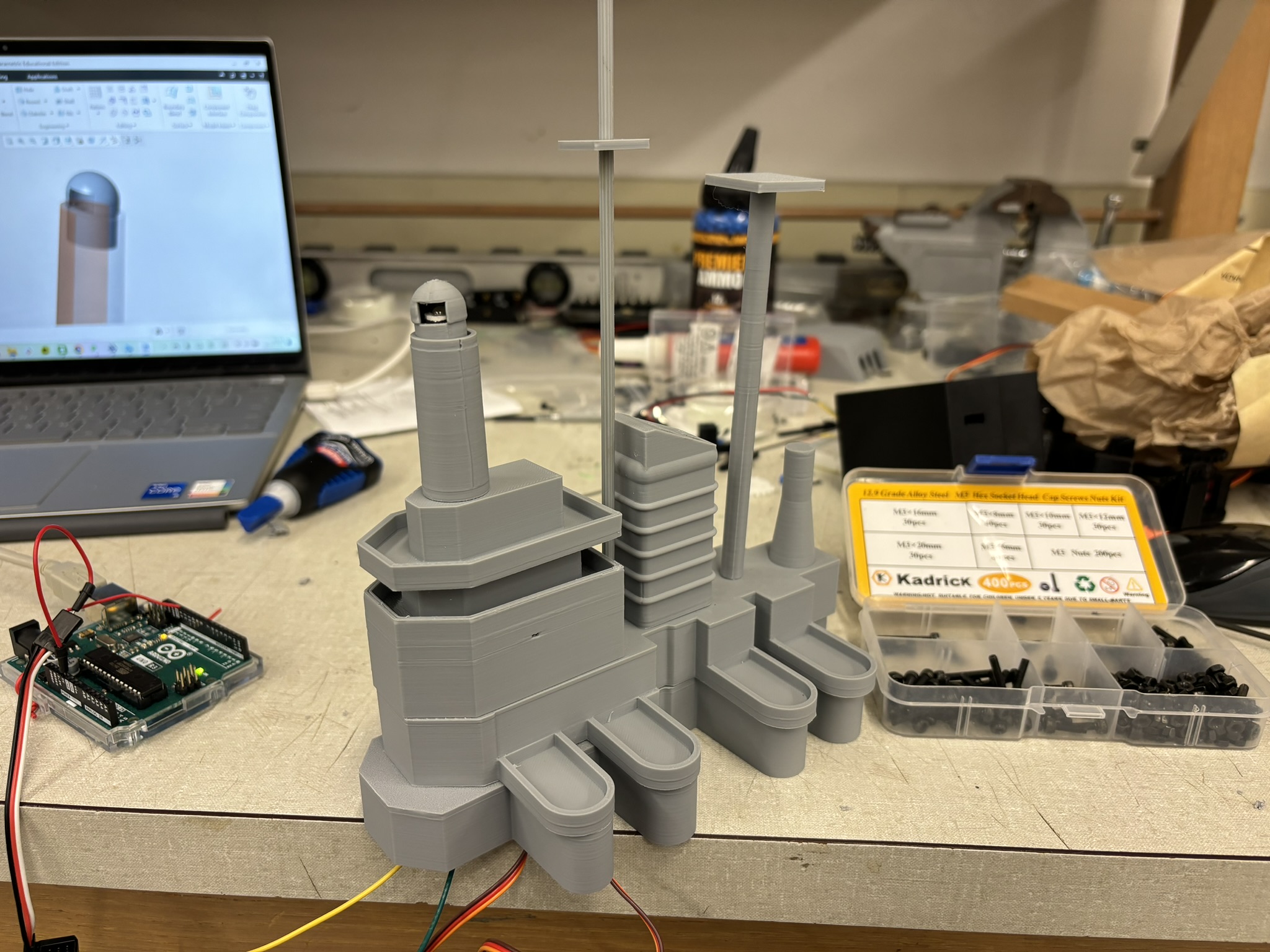

Total length of the ship hull is 700 mm. I split it into three parts so it can fit on the printer. Thanks to high speed 3D printer, each section just needs 5 hours to print, just half of the time than before.

1.3 Bridge

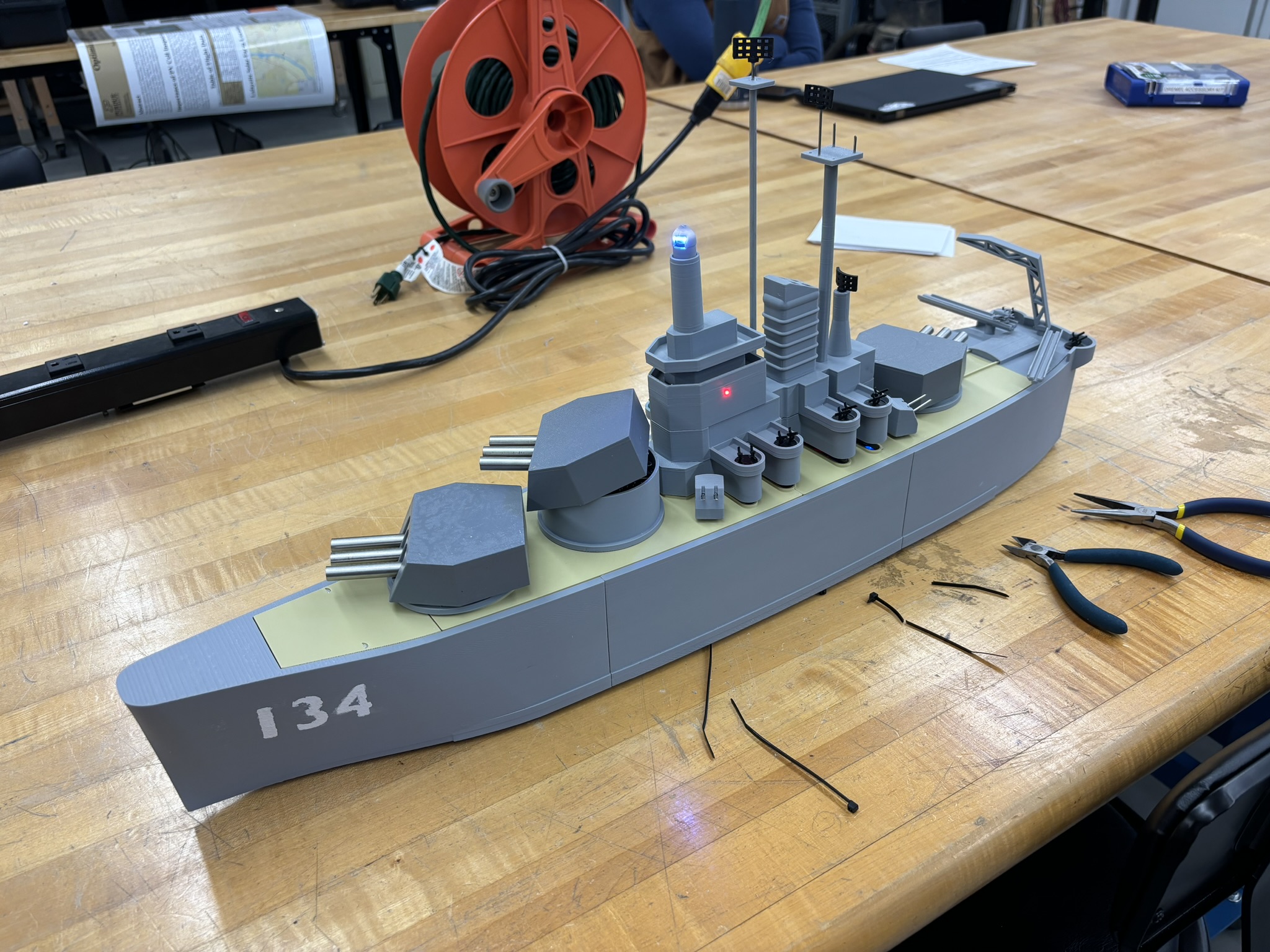

The bridge contains several levels, and they are connected with super glue. It also has several towers with rotating lights and radar and two navigation lights with green on the right and red on the left. Two rotating features are done by two 360-degree servos.

1.4 Driving

There’s a steerable driving wheel on the back. But the motor was too weak.

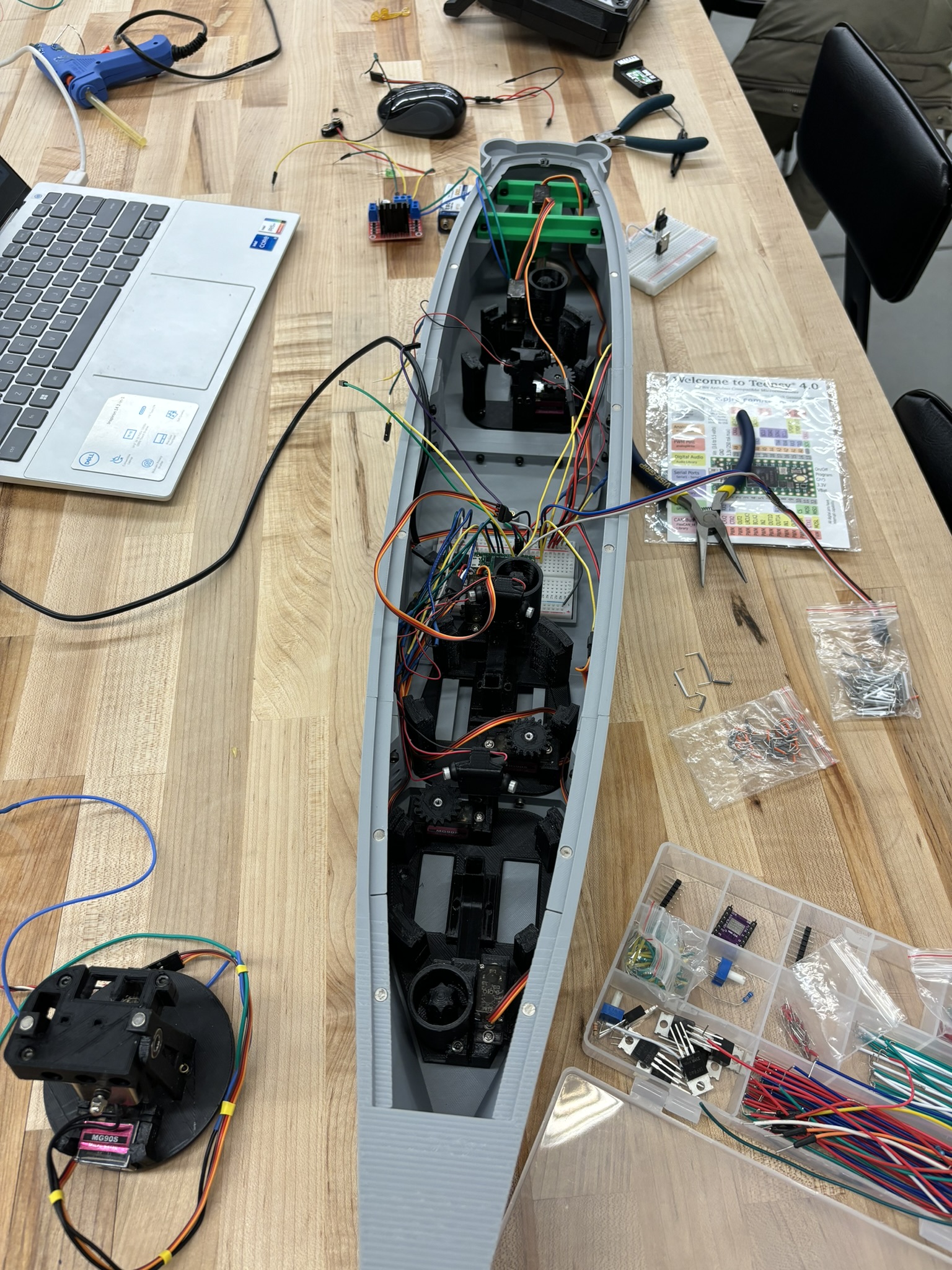

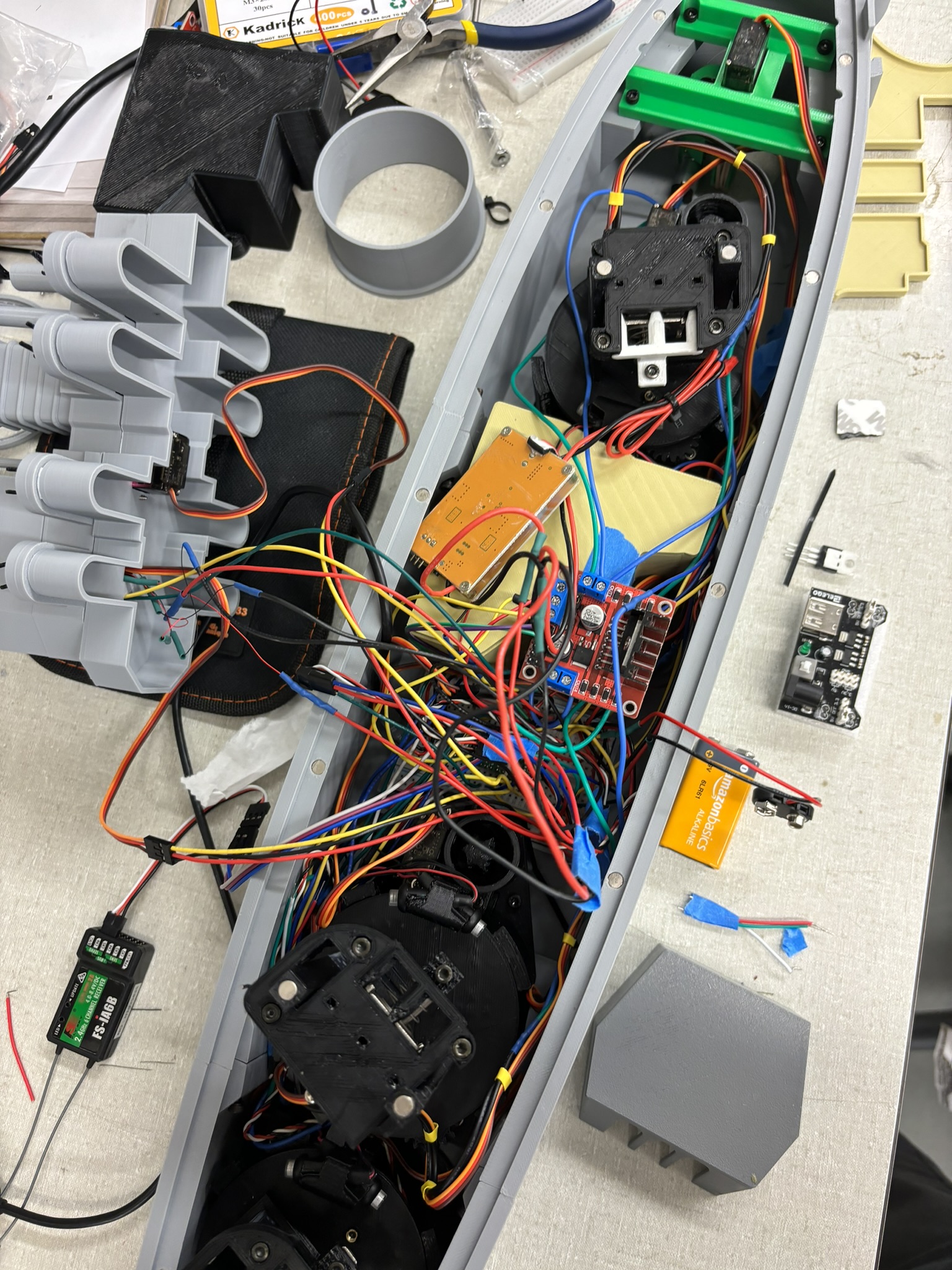

2. Electronics and Control

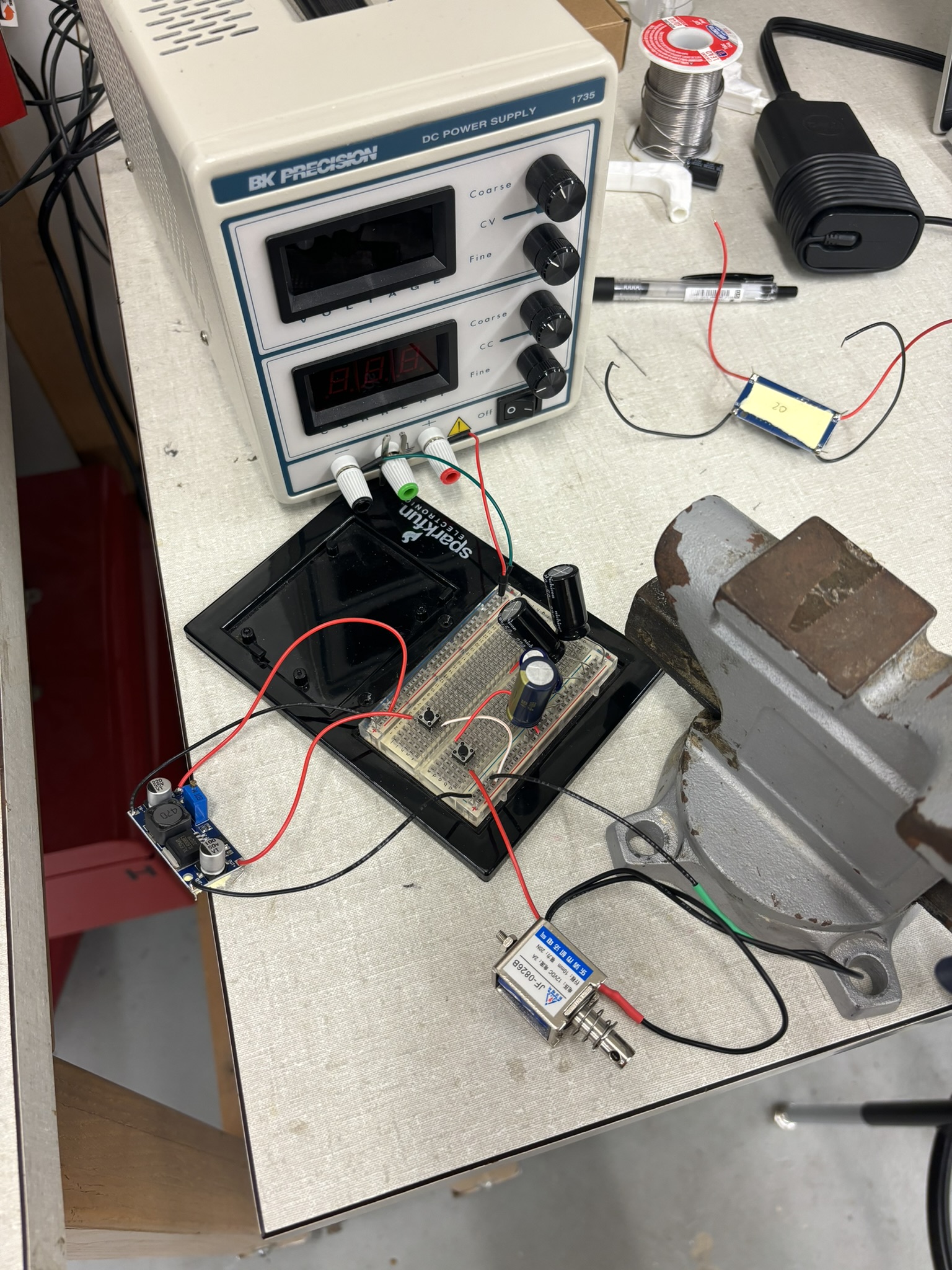

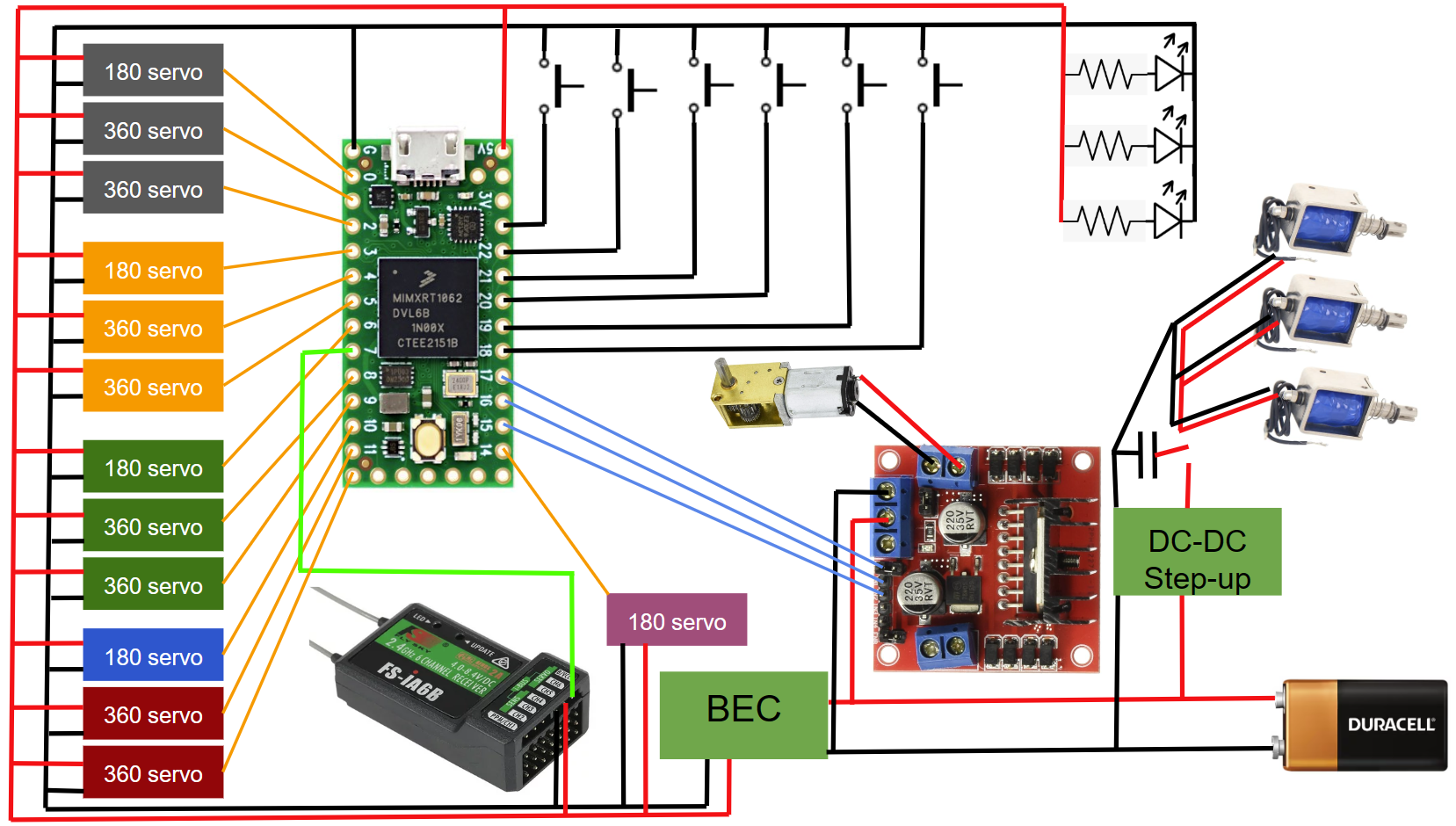

2.1 i-Bus and Teensy 4.0

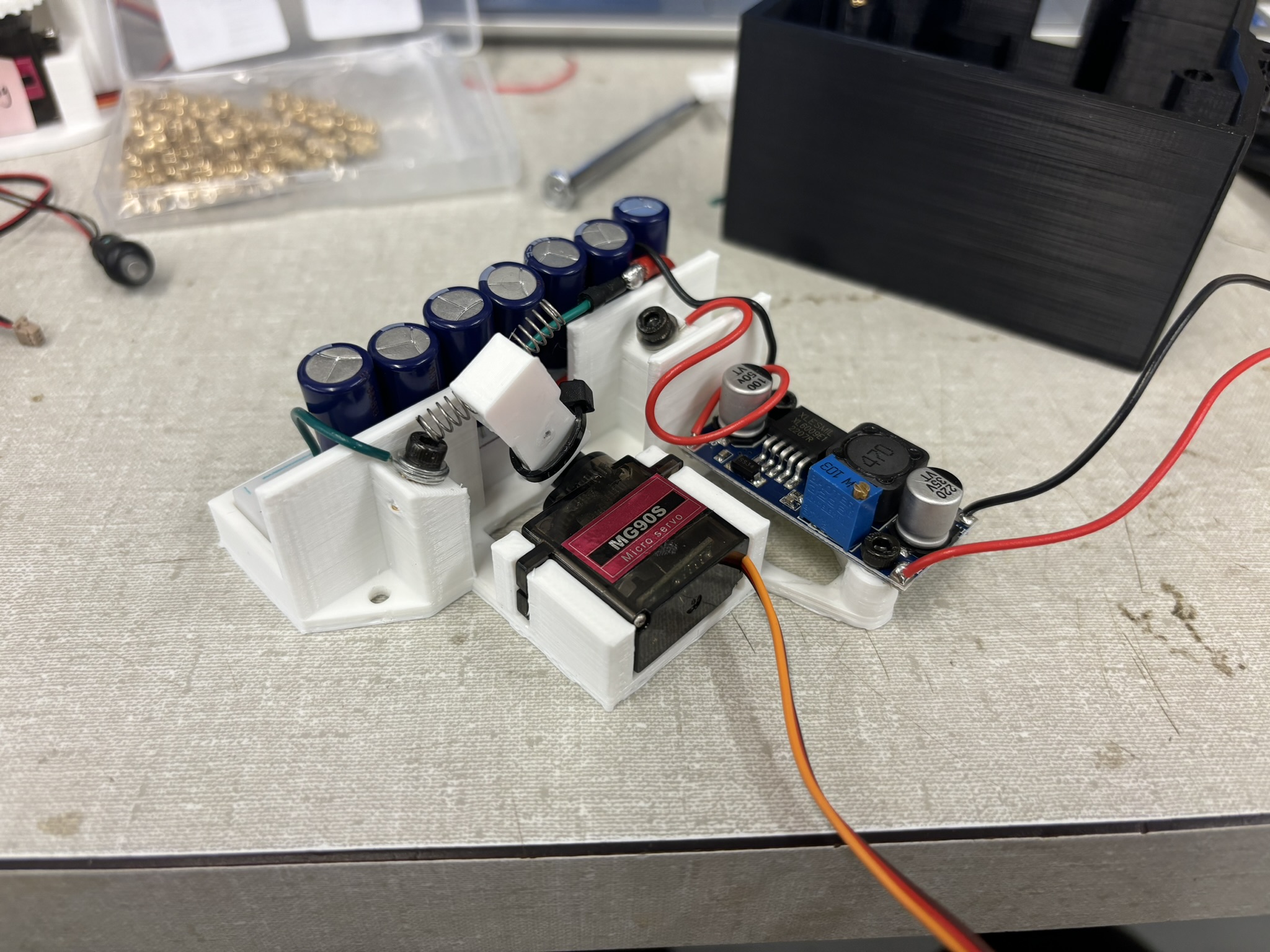

Using one single wire, the RC receiver can transmit data of 10 channels to Teensy 4.0 RX, and we can process those command to control them. Each turret need one 180 degree servo for pitch and two 360 servos for yaw and loading. Each turret has two switches to detect if the turret is at the extreme position.

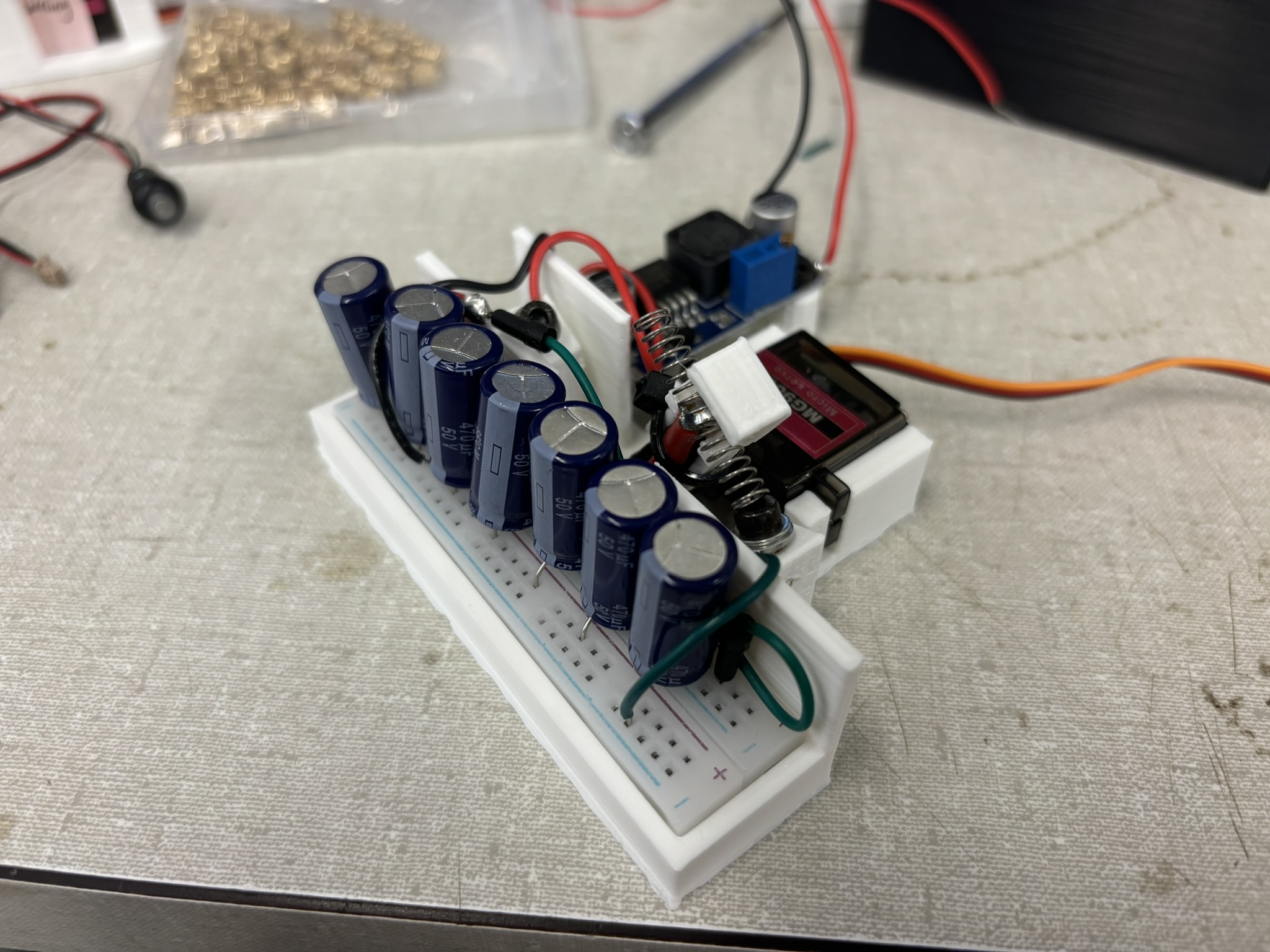

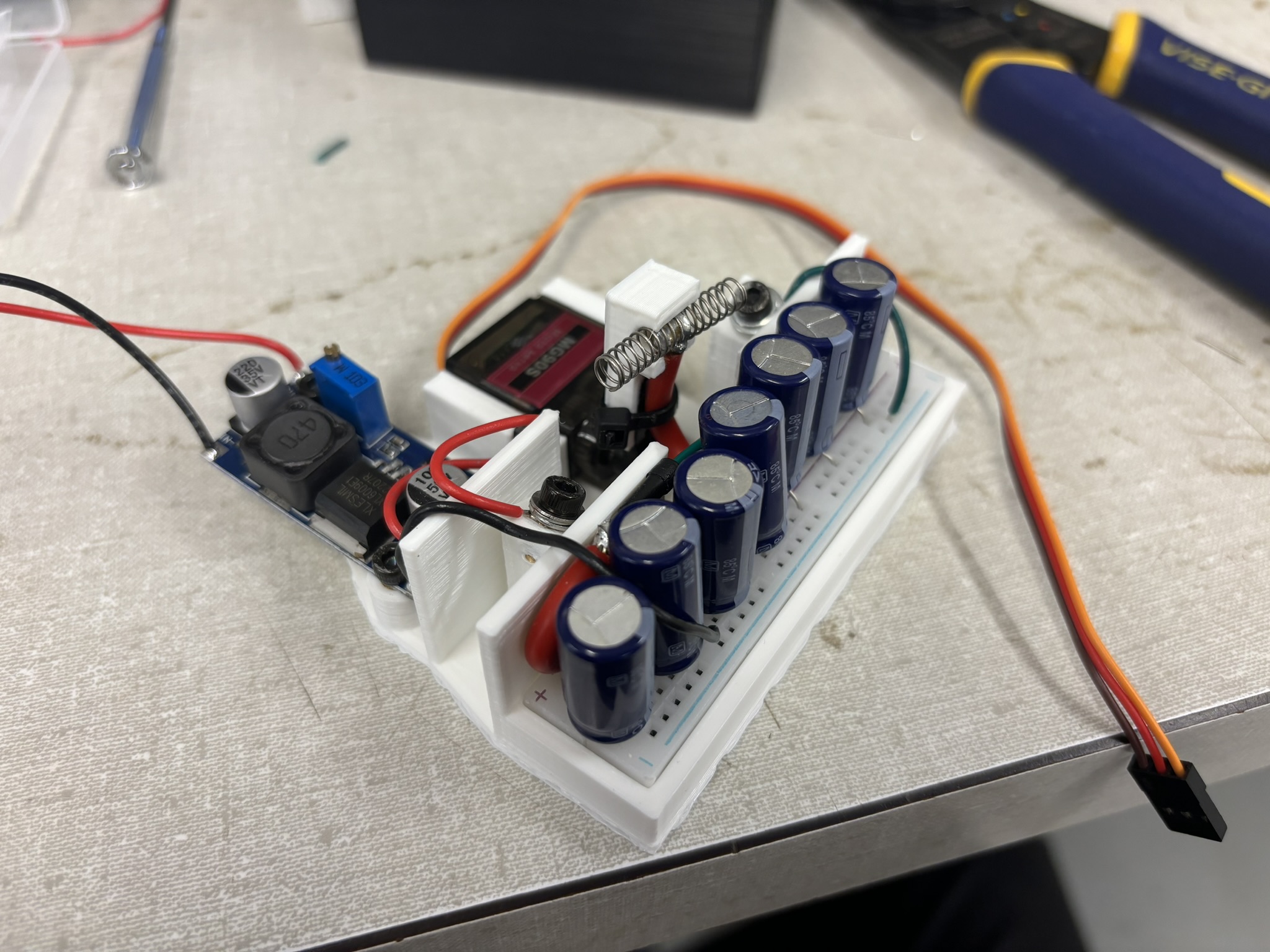

2.2 Firing Control

Firing control is done by using a 180 servo (purple). It has three positions: charging, neutral, and discharging. See Figure 1.1.20.

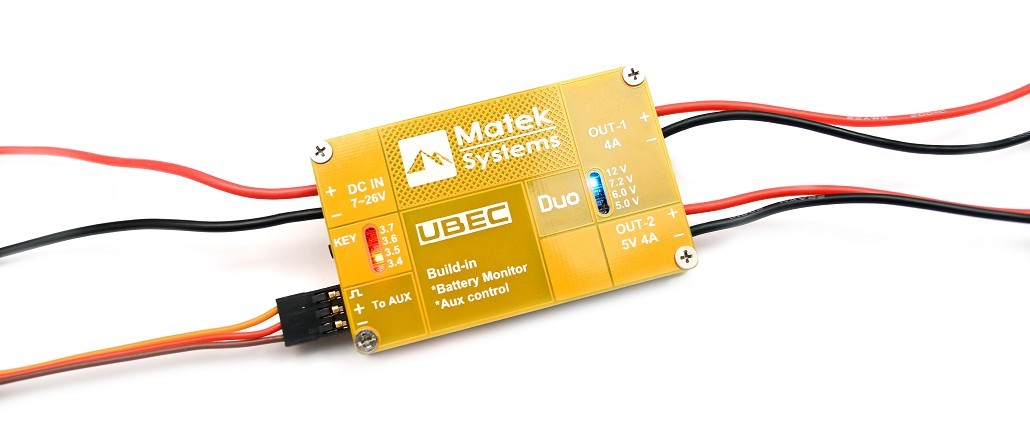

2.3 Matek Systems UBEC DUO, 4A/5~12V & 4A/5V

It’s a battery elimination circuit that can transfer high voltage to 5V with max output current of 4A. Other 5V supply unit can’t support 13 servos, but this can.

3. Assembly

4. Conclusion

- Due to the size limitation, it’s so hard to put everything in there. It doesn’t even have the space for magazines for each turret, larger and stronger motor for the driving wheel, and all the wires.

- Since there’s no enough space, the wires are pushing the bridge up, so the bridge can’t touch the deck.

- The cheap 2 kg-cm servo just killed itself. It became very hot, and then there’s no resistance on the arm. This happens on the turning servo in turret Z, pitch servo in turret A, and firing control servo.

- The LED is flashing for some reason. It’s just a LED and a resistor in series and connected to 5V.

- The case for the rotating light had a dent for some reason. We thought the LED was too hot and it’s melting it, but it’s just warm and safe to touch with hand.